Information

dict2_description

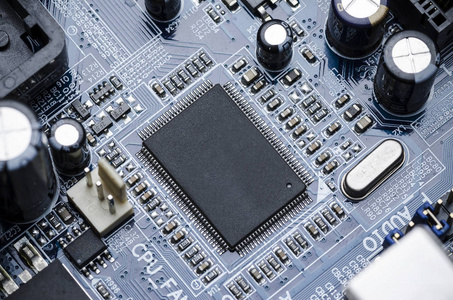

What material is a chip resistor made of?

2024-12-20

0

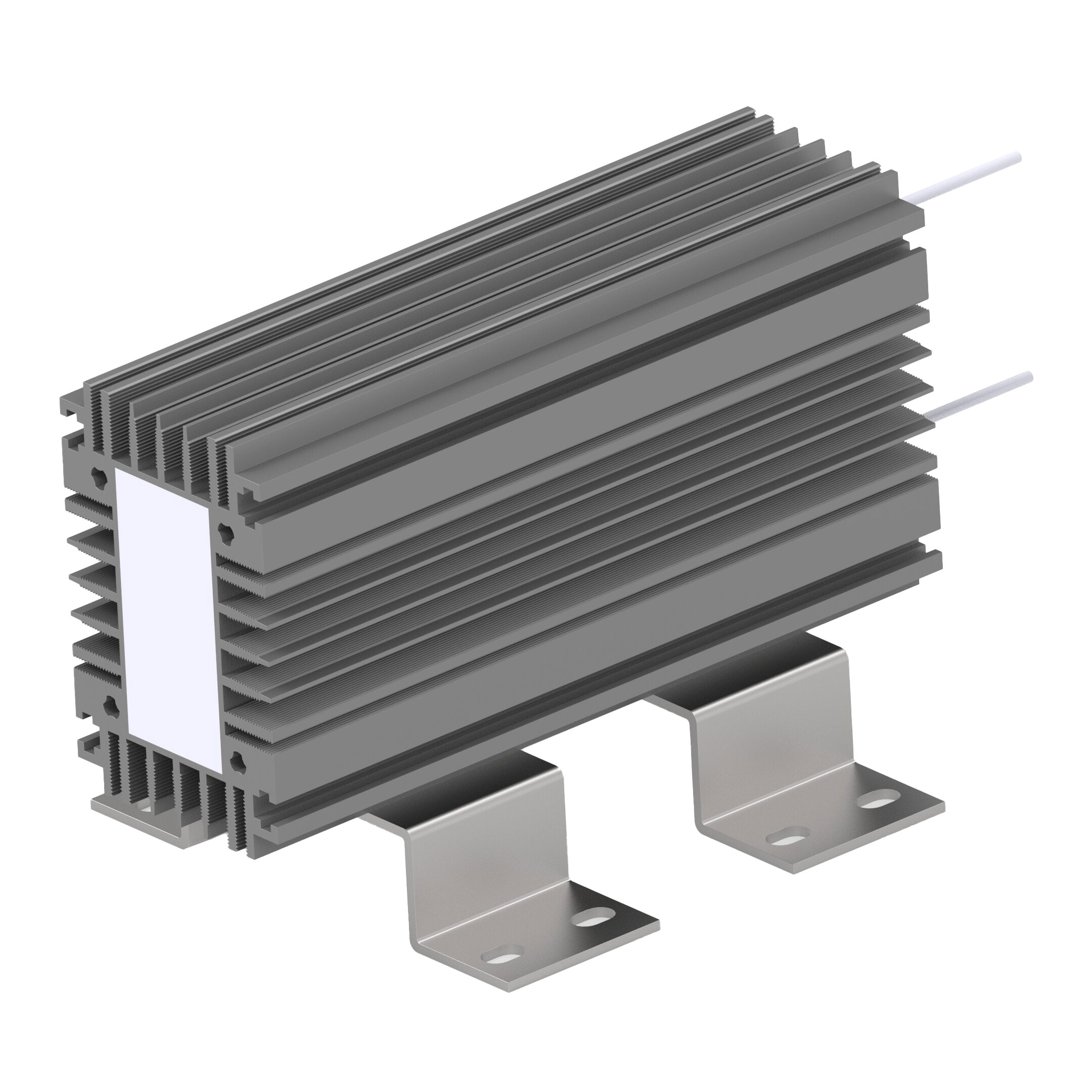

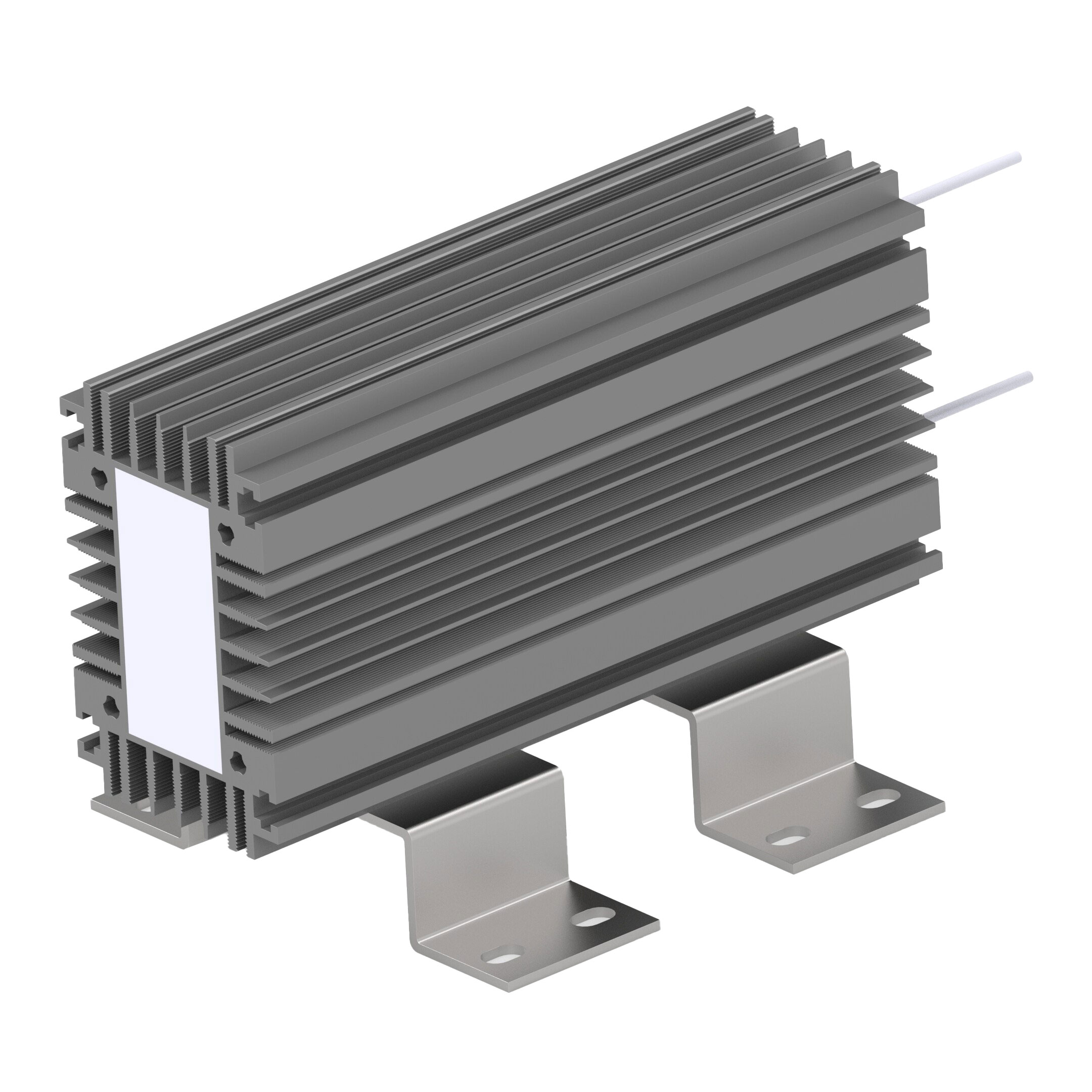

What kind of product is a cement resistor?

2024-12-19

0

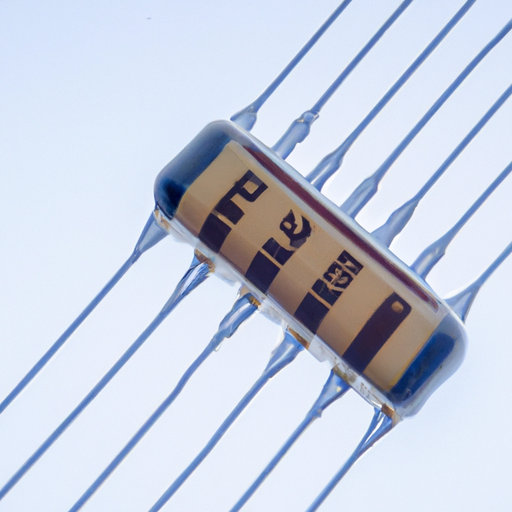

How does a color ring resistor work?

2024-12-15

0

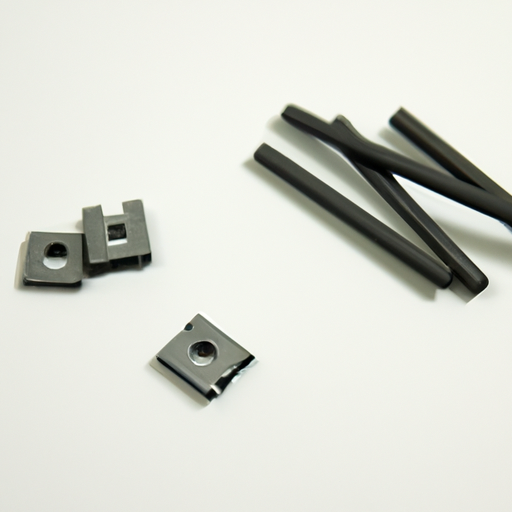

An article to help you understand the pen mold core

2024-12-14

0

dict3_title

dict3_description