The Manufacturing Process of Braking Resistors

I. Introduction

Braking resistors are essential components in various electrical systems, serving a critical role in energy management and safety. These resistors dissipate excess energy generated during braking, particularly in electric vehicles and industrial machinery, preventing damage to the system and enhancing performance. Understanding the manufacturing process of braking resistors is vital for appreciating their functionality and the technology behind them. This blog post will explore the intricacies of braking resistors, the materials used in their production, and the detailed steps involved in their manufacturing.

II. Understanding Braking Resistors

A. Function and Application in Various Industries

Braking resistors are primarily used to manage energy during deceleration. When an electric motor slows down, it generates excess energy that must be dissipated to prevent overheating and potential damage. Braking resistors convert this energy into heat, allowing for safe operation. Their applications span several industries:

1. **Electric Vehicles**: In electric and hybrid vehicles, braking resistors play a crucial role in regenerative braking systems, where they help manage the energy produced during braking, ensuring efficient energy recovery and preventing system overload.

2. **Industrial Machinery**: In manufacturing and heavy machinery, braking resistors are used to control the speed of motors and prevent sudden stops that could lead to mechanical failure or safety hazards.

3. **Renewable Energy Systems**: In wind turbines and solar inverters, braking resistors help manage energy fluctuations, ensuring stable operation and protecting sensitive electronic components.

B. Types of Braking Resistors

Braking resistors come in various types, each suited for specific applications:

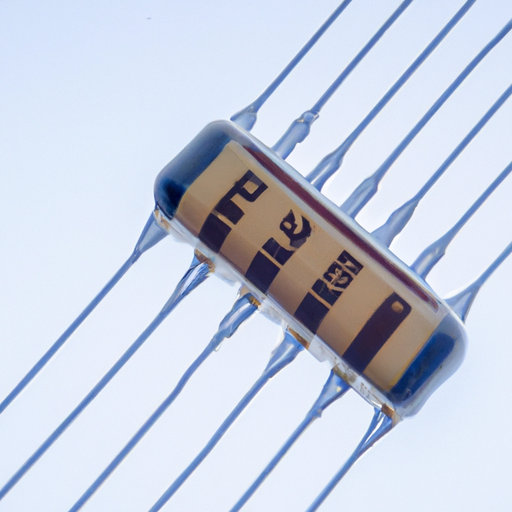

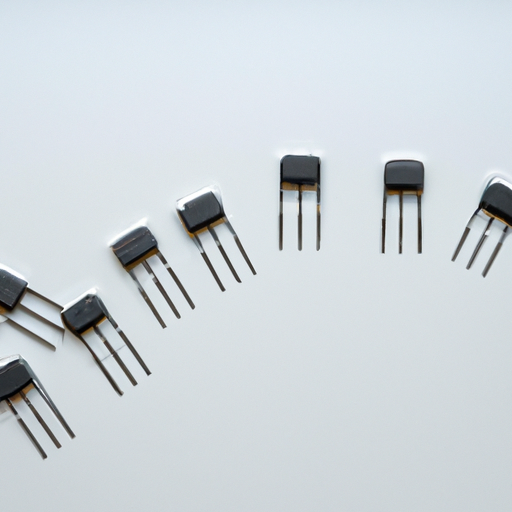

1. **Wire-wound Resistors**: These resistors are made by winding resistance wire around a core. They are known for their high power ratings and ability to handle significant heat dissipation.

2. **Ceramic Resistors**: Constructed from ceramic materials, these resistors offer excellent thermal stability and are often used in high-temperature applications.

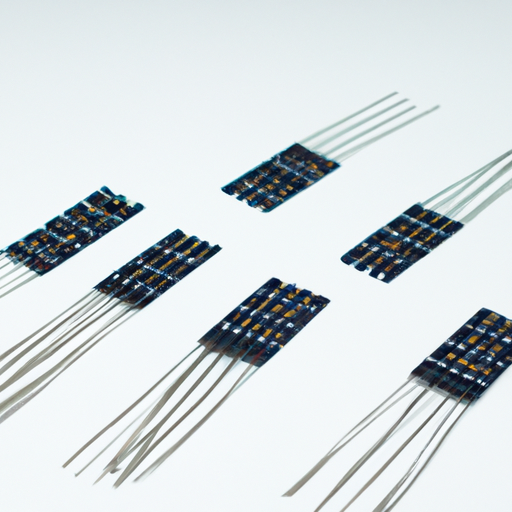

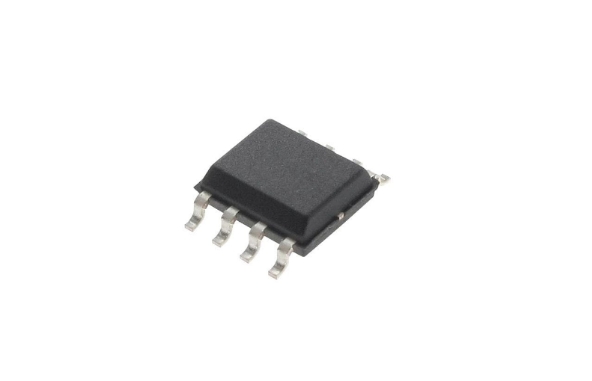

3. **Thick Film Resistors**: These resistors are made by applying a thick film of resistive material onto a substrate. They are compact and suitable for applications where space is limited.

III. Materials Used in Braking Resistor Manufacturing

The performance and reliability of braking resistors depend significantly on the materials used in their construction.

A. Conductive Materials

1. **Copper and Aluminum**: These metals are commonly used for their excellent electrical conductivity. Copper is often preferred for its superior conductivity, while aluminum is lighter and more cost-effective.

2. **Resistance Wire**: Nickel-chromium alloys are frequently used as resistance wire due to their high-temperature stability and resistance to oxidation, making them ideal for high-power applications.

B. Insulating Materials

1. **Ceramics**: Ceramic materials are used for their high thermal resistance and electrical insulation properties, ensuring that the heat generated by the resistor does not affect other components.

2. **Epoxy Resins**: These resins provide excellent insulation and mechanical strength, often used to encapsulate resistors and protect them from environmental factors.

C. Heat Dissipation Materials

1. **Heat Sinks**: These components are designed to absorb and dissipate heat away from the resistor, preventing overheating and ensuring reliable operation.

2. **Thermal Interface Materials**: These materials enhance the thermal connection between the resistor and the heat sink, improving heat transfer efficiency.

IV. The Manufacturing Process

The manufacturing process of braking resistors involves several critical steps, each contributing to the final product's quality and performance.

A. Design and Engineering

1. **Specifications and Requirements**: The manufacturing process begins with defining the specifications based on the intended application. This includes power ratings, resistance values, and thermal management requirements.

2. **Computer-Aided Design (CAD) Modeling**: Engineers use CAD software to create detailed models of the braking resistor, allowing for precise design and simulation of performance under various conditions.

B. Material Preparation

1. **Sourcing Raw Materials**: Manufacturers source high-quality conductive and insulating materials from reliable suppliers to ensure the performance and longevity of the resistors.

2. **Cutting and Shaping Conductive and Insulating Materials**: Raw materials are cut and shaped according to the specifications defined in the design phase. This may involve machining, stamping, or other fabrication techniques.

C. Assembly Process

1. **Winding the Resistance Wire**: For wire-wound resistors, the resistance wire is carefully wound around a core to achieve the desired resistance value. This process requires precision to ensure uniformity and performance.

2. **Mounting Components onto a Substrate**: The assembled components, including the resistance wire and insulating materials, are mounted onto a substrate. This substrate provides structural support and electrical insulation.

3. **Applying Insulating Materials**: Insulating materials, such as ceramics or epoxy resins, are applied to encapsulate the resistor, providing protection against environmental factors and enhancing thermal management.

D. Testing and Quality Control

1. **Electrical Testing**: Each braking resistor undergoes rigorous electrical testing to verify its resistance, voltage, and current ratings. This ensures that the resistor meets the specified performance criteria.

2. **Thermal Testing**: Thermal testing evaluates the resistor's heat dissipation capabilities and endurance under load conditions. This step is crucial for ensuring reliability in real-world applications.

3. **Visual Inspection and Compliance Checks**: A thorough visual inspection is conducted to identify any defects or inconsistencies. Compliance checks ensure that the resistors meet industry standards and regulations.

V. Finalization and Packaging

A. Final Assembly and Integration

Once testing is complete, the braking resistors undergo final assembly, where any additional components, such as heat sinks or connectors, are integrated into the final product.

B. Packaging for Shipment

Braking resistors are carefully packaged to prevent damage during transportation. Packaging materials are selected to provide adequate protection while being environmentally friendly.

C. Documentation and Certification

Manufacturers provide documentation detailing the specifications, testing results, and certifications for each batch of braking resistors. This documentation is essential for customers to ensure compliance with industry standards.

VI. Conclusion

Braking resistors are vital components in modern electrical systems, playing a crucial role in energy management and safety across various industries. Understanding the manufacturing process of these resistors—from material selection to final testing—highlights the complexity and precision involved in their production. As technology advances, we can expect to see innovations in braking resistor design and manufacturing, leading to improved performance, efficiency, and sustainability in electrical systems.

VII. References

1. Industry standards and guidelines related to braking resistors.

2. Relevant literature and studies on braking resistors and their applications.

3. Manufacturer resources and technical specifications for braking resistors.

In conclusion, the manufacturing process of braking resistors is a sophisticated blend of engineering, material science, and quality control, ensuring that these components perform reliably in critical applications. As industries continue to evolve, the demand for efficient and effective braking resistors will only grow, driving further advancements in their technology and manufacturing processes.