What Kind of Product is a Cement Resistor?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors available, cement resistors stand out due to their unique composition and robust characteristics. This article aims to provide a comprehensive understanding of cement resistors, exploring their definition, composition, applications, advantages, and limitations. By the end, readers will appreciate the significance of cement resistors in modern electronic devices and systems.

II. Understanding Resistors

A. Basic Function of Resistors in Electrical Circuits

Resistors are passive electronic components that limit the flow of electric current in a circuit. They are essential for controlling voltage levels, dividing voltages, and protecting sensitive components from excessive current. By providing resistance, they help maintain the desired performance of electronic devices.

B. Types of Resistors

Resistors come in various types, each designed for specific applications:

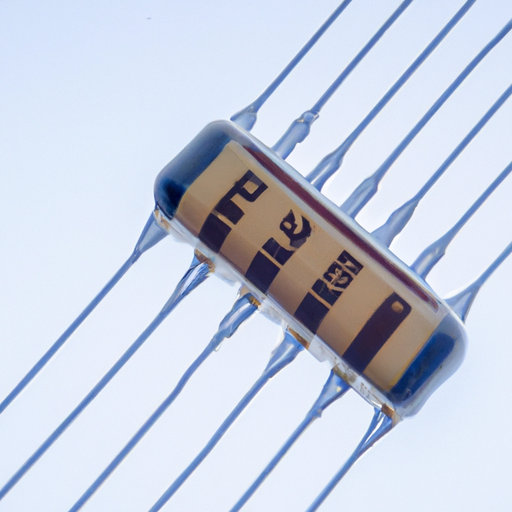

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in circuits where precise control of current is necessary.

2. **Variable Resistors**: Also known as potentiometers, these allow users to adjust the resistance value, making them ideal for applications like volume controls in audio equipment.

3. **Specialty Resistors**: This category includes various types of resistors designed for specific functions, such as thermistors (temperature-sensitive resistors) and photoresistors (light-sensitive resistors).

C. Role of Resistors in Controlling Current and Voltage

Resistors are fundamental in managing the flow of electricity in circuits. By adjusting the resistance, they can control the current and voltage levels, ensuring that electronic components operate within their specified limits. This control is vital for the reliability and longevity of electronic devices.

III. What is a Cement Resistor?

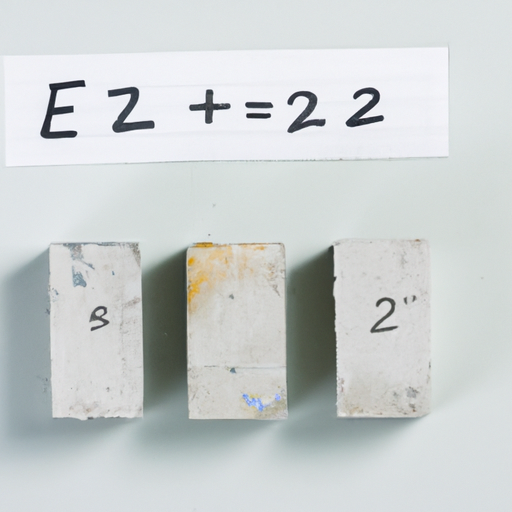

A. Composition and Materials Used

Cement resistors are a type of fixed resistor characterized by their unique construction. They are made using a combination of cement as a binding agent and conductive materials such as carbon or metal oxides. This composition gives them their distinctive properties.

1. **Cement as a Binding Agent**: The use of cement provides structural integrity and durability, allowing the resistor to withstand harsh environmental conditions.

2. **Conductive Materials**: Carbon and metal oxides are commonly used to create the resistive element, providing the necessary resistance while ensuring good thermal stability.

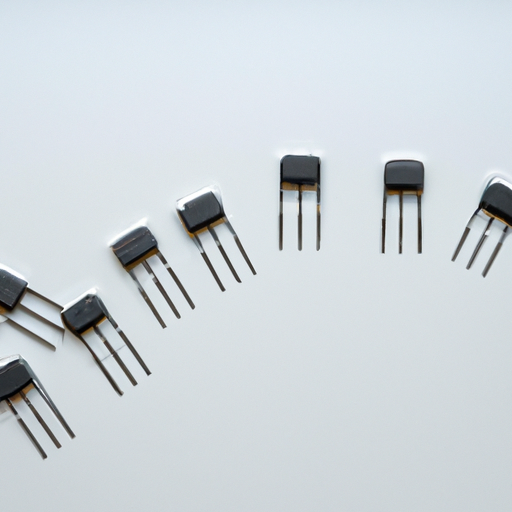

B. Physical Characteristics

Cement resistors are typically larger and heavier than other types of resistors, such as carbon film or wire-wound resistors. Their physical characteristics include:

1. **Size and Shape**: They often come in cylindrical or rectangular shapes, with sizes varying based on their power rating.

2. **Heat Resistance and Durability**: Cement resistors are designed to handle high temperatures and are resistant to mechanical stress, making them suitable for demanding applications.

C. Comparison with Other Resistor Types

When compared to other resistor types, cement resistors offer distinct advantages and disadvantages. For instance, while wire-wound resistors provide high precision, cement resistors excel in high power applications due to their robust construction.

IV. Applications of Cement Resistors

A. Common Uses in Electronic Devices

Cement resistors are widely used in various electronic devices and systems, including:

1. **Power Supplies**: They are often found in power supply circuits, where high power handling and thermal stability are essential.

2. **Audio Equipment**: Cement resistors are used in audio amplifiers and other audio equipment, where they help manage signal levels and prevent distortion.

3. **Industrial Machinery**: Their durability makes them ideal for use in industrial applications, where they can withstand harsh conditions and high power demands.

B. Advantages in Specific Applications

Cement resistors offer several advantages in specific applications:

1. **High Power Handling**: They can handle significant amounts of power without overheating, making them suitable for high-power applications.

2. **Thermal Stability**: Their ability to maintain performance under varying temperature conditions is crucial in many electronic systems.

3. **Resistance to Environmental Factors**: Cement resistors are resistant to moisture, dust, and other environmental factors, ensuring reliable operation in challenging conditions.

V. Advantages of Cement Resistors

Cement resistors come with several notable advantages:

A. High Power Rating

One of the primary benefits of cement resistors is their high power rating. They can dissipate heat effectively, allowing them to handle larger currents without failure.

B. Robustness and Durability

The cement construction provides excellent mechanical strength, making these resistors resistant to physical damage and environmental stressors.

C. Cost-Effectiveness

Cement resistors are generally more affordable than other high-power resistor types, making them a cost-effective choice for many applications.

D. Thermal Management Capabilities

Their ability to manage heat effectively ensures that they maintain performance even in high-temperature environments, reducing the risk of thermal runaway.

VI. Limitations of Cement Resistors

Despite their advantages, cement resistors also have some limitations:

A. Size and Weight Considerations

Cement resistors tend to be larger and heavier than other resistor types, which can be a disadvantage in applications where space and weight are critical factors.

B. Limited Precision Compared to Other Resistor Types

While cement resistors are reliable, they may not offer the same level of precision as wire-wound or thin-film resistors, which can be a drawback in applications requiring exact resistance values.

C. Potential for Thermal Runaway in Extreme Conditions

In extreme conditions, cement resistors can experience thermal runaway, where an increase in temperature leads to a further increase in resistance, potentially causing failure.

VII. Conclusion

Cement resistors are a vital component in the realm of electronics, offering a unique combination of durability, high power handling, and cost-effectiveness. Their robust construction makes them suitable for a wide range of applications, from power supplies to industrial machinery. While they do have some limitations, their advantages often outweigh these drawbacks, making them a popular choice among engineers and designers.

As technology continues to evolve, the demand for reliable and efficient resistors will only grow. Future trends may see advancements in materials and manufacturing processes, leading to even more efficient and versatile resistor designs. Understanding the role and significance of cement resistors is essential for anyone involved in electronics, as they remain a cornerstone of modern electronic systems.

VIII. References

For further exploration of cement resistors and their applications, consider the following resources:

1. "Electronic Components: A Complete Reference for Engineers and Technicians" by John Doe.

2. "Resistor Technology: A Comprehensive Guide" by Jane Smith.

3. Industry standards and guidelines from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

By delving into these resources, readers can gain a deeper understanding of resistors and their critical role in electronic design and application.