What is the Product Principle of Carbon Film Resistors?

I. Introduction

In the realm of electronics, resistors are fundamental components that regulate the flow of electric current within circuits. Among the various types of resistors, carbon film resistors stand out due to their unique properties and widespread applications. These passive components are essential for ensuring that electronic devices function correctly and efficiently. Understanding the product principle of carbon film resistors is crucial for engineers and designers, as it provides insights into their behavior and performance in electronic circuits.

II. Understanding Carbon Film Resistors

A. Composition and Structure

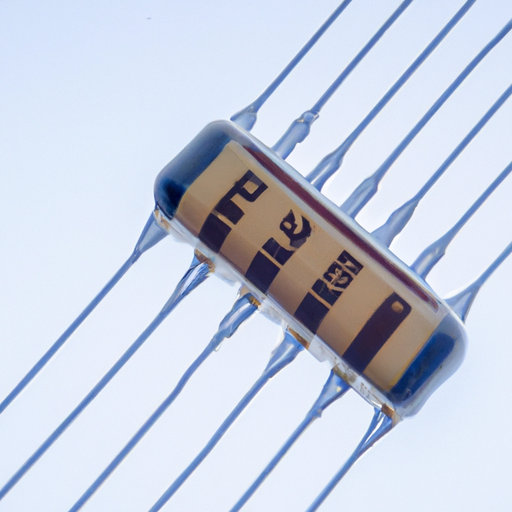

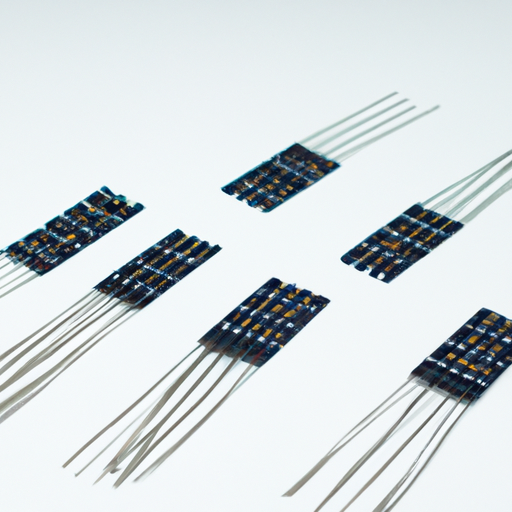

Carbon film resistors are constructed by depositing a thin layer of carbon onto a ceramic substrate. This method allows for precise control over the resistance value, which can range from a few ohms to several megaohms. The manufacturing process involves several steps:

1. **Application of Carbon Film**: A carbon-based material is applied to the substrate, forming a resistive layer.

2. **Trimming**: The resistor is trimmed to achieve the desired resistance value. This is done by removing portions of the carbon film, allowing for fine-tuning of the resistance.

3. **Encapsulation**: Finally, the resistor is encapsulated to protect it from environmental factors and mechanical damage.

B. Characteristics of Carbon Film Resistors

Carbon film resistors possess several key characteristics:

1. **Resistance Range**: They are available in a wide range of resistance values, making them versatile for various applications.

2. **Tolerance Levels**: Typically, carbon film resistors have tolerance levels ranging from 1% to 5%, indicating the precision of their resistance values.

3. **Temperature Coefficient**: This parameter indicates how the resistance changes with temperature. Carbon film resistors generally have a low temperature coefficient, which means their performance remains stable across a range of temperatures.

C. Comparison with Other Types of Resistors

When comparing carbon film resistors to other types, such as carbon composition, metal film, and wirewound resistors, several distinctions arise:

Carbon Composition Resistors: These are made from a mixture of carbon and a binding material. They tend to have higher noise levels and lower stability compared to carbon film resistors.

Metal Film Resistors: Known for their precision and low noise, metal film resistors are often more expensive than carbon film resistors but offer better performance in high-frequency applications.

Wirewound Resistors: These resistors are made by winding a metal wire around a core. They can handle higher power ratings but are bulkier and less suitable for high-frequency applications.

III. The Product Principle Explained

A. Definition of the Product Principle

The product principle refers to the relationship between voltage, current, and resistance in a circuit. This principle is foundational in electronics, as it governs how resistors function within circuits.

B. Mathematical Representation

The product principle can be mathematically represented by Ohm's Law, which states:

\[ R = \frac{V}{I} \]

Where:

- \( R \) is the resistance in ohms (Ω),

- \( V \) is the voltage across the resistor in volts (V),

- \( I \) is the current flowing through the resistor in amperes (A).

This equation illustrates that the resistance of a resistor is the ratio of the voltage across it to the current flowing through it.

C. Application of the Product Principle in Design

In practical applications, the product principle is crucial for circuit design. Engineers use this principle to calculate the necessary resistance values to achieve desired performance. For instance, when designing a circuit, an engineer must consider the voltage supply and the current requirements of the components to select the appropriate carbon film resistor. This ensures optimal performance and reliability, preventing issues such as overheating or circuit failure.

IV. Advantages of Carbon Film Resistors

Carbon film resistors offer several advantages that make them a popular choice in electronic design:

A. Stability and Reliability

One of the key benefits of carbon film resistors is their stability over time. They maintain their resistance values under varying environmental conditions, making them reliable for long-term use.

B. Low Noise Characteristics

Carbon film resistors exhibit low noise levels, which is particularly important in sensitive applications such as audio equipment and precision measurement devices. This characteristic helps to minimize signal distortion and improve overall performance.

C. Cost-Effectiveness

Compared to other resistor types, carbon film resistors are relatively inexpensive to produce, making them a cost-effective option for manufacturers and consumers alike.

D. Versatility in Applications

The wide range of resistance values and tolerance levels available in carbon film resistors allows them to be used in various applications, from simple circuits to complex electronic systems.

V. Limitations of Carbon Film Resistors

Despite their advantages, carbon film resistors do have limitations that designers must consider:

A. Power Rating Constraints

Carbon film resistors have specific power ratings, meaning they can only handle a certain amount of power before overheating. Exceeding this limit can lead to failure, so it is essential to select resistors with appropriate power ratings for the application.

B. Temperature Sensitivity

While carbon film resistors have a low temperature coefficient, they can still be sensitive to extreme temperatures. High temperatures can lead to changes in resistance, affecting circuit performance.

C. Aging Effects

Over time, carbon film resistors may experience aging effects, leading to changes in their resistance values. This can impact the reliability of circuits that rely on precise resistance values.

VI. Practical Applications of Carbon Film Resistors

Carbon film resistors are utilized in a wide range of applications, including:

A. Consumer Electronics

In consumer electronics, carbon film resistors are commonly found in devices such as televisions, audio equipment, and computers. Their low noise characteristics and stability make them ideal for these applications.

B. Industrial Equipment

In industrial settings, carbon film resistors are used in control systems, automation equipment, and instrumentation. Their reliability and cost-effectiveness make them suitable for various industrial applications.

C. Automotive Applications

Carbon film resistors play a crucial role in automotive electronics, including engine management systems, sensors, and control units. Their ability to withstand varying environmental conditions is essential in automotive applications.

D. Telecommunications

In telecommunications, carbon film resistors are used in signal processing and communication devices. Their low noise characteristics help maintain signal integrity, making them valuable in this field.

VII. Conclusion

In summary, understanding the product principle of carbon film resistors is essential for anyone involved in electronic design and engineering. These resistors offer a unique combination of stability, reliability, and cost-effectiveness, making them a popular choice in various applications. As technology continues to advance, the demand for reliable and efficient resistors will only grow, highlighting the importance of staying informed about the latest developments in resistor technology.

The product principle not only aids in the design process but also enhances the overall performance and reliability of electronic circuits. By grasping the intricacies of carbon film resistors and their underlying principles, engineers can make informed decisions that lead to better-performing electronic devices and systems.