What are the Product Standards for Fuse Resistors?

I. Introduction

A. Definition of Fuse Resistors

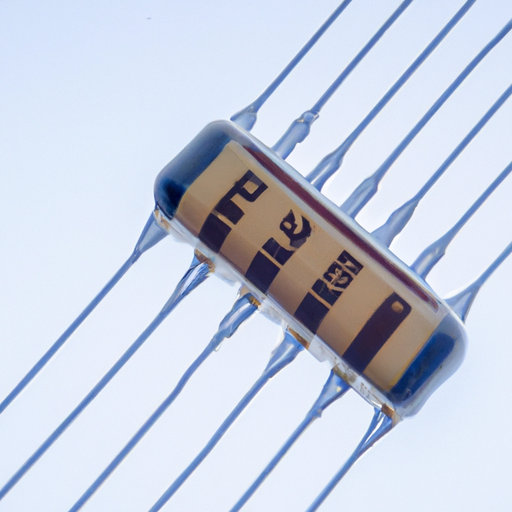

Fuse resistors are specialized components that combine the functions of a resistor and a fuse. They are designed to limit current in electrical circuits while providing overcurrent protection. When the current exceeds a predetermined threshold, the fuse resistor will "blow," effectively interrupting the circuit and preventing damage to other components.

B. Importance of Product Standards

Product standards are essential in ensuring the safety, reliability, and performance of electrical components, including fuse resistors. These standards help manufacturers produce consistent products that meet specific safety and performance criteria, thereby protecting consumers and industries alike. Compliance with these standards is crucial for manufacturers to gain market acceptance and ensure the longevity of their products.

C. Overview of the Article

This article will explore the various product standards for fuse resistors, including their functions, types, regulatory bodies, key standards, testing processes, industry applications, and the challenges faced in maintaining compliance.

II. Understanding Fuse Resistors

A. Function and Purpose

1. Role in Electrical Circuits

Fuse resistors play a critical role in electrical circuits by limiting the amount of current that can flow through a circuit. This function is vital in preventing overheating and potential damage to sensitive components. By integrating the functions of a resistor and a fuse, these components provide a compact solution for current management and protection.

2. Protection Mechanism

The protection mechanism of fuse resistors is straightforward. When the current flowing through the resistor exceeds its rated capacity, the heat generated causes the resistor to fail, effectively breaking the circuit. This action protects downstream components from excessive current, which could lead to failure or even fire hazards.

B. Types of Fuse Resistors

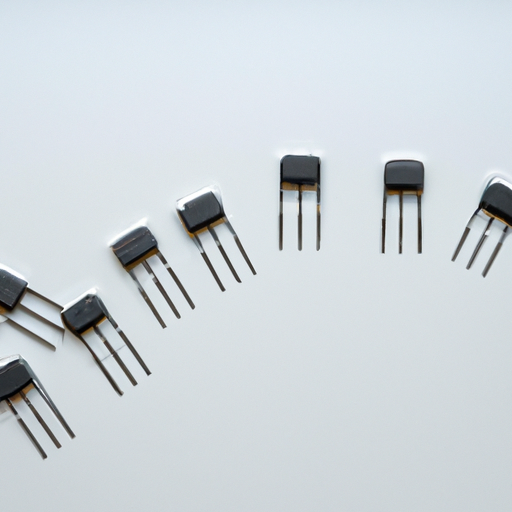

1. Wirewound Fuse Resistors

Wirewound fuse resistors are constructed using a wire wound around a ceramic or insulating core. They offer high precision and stability, making them suitable for applications requiring accurate resistance values. However, they may have slower response times compared to other types.

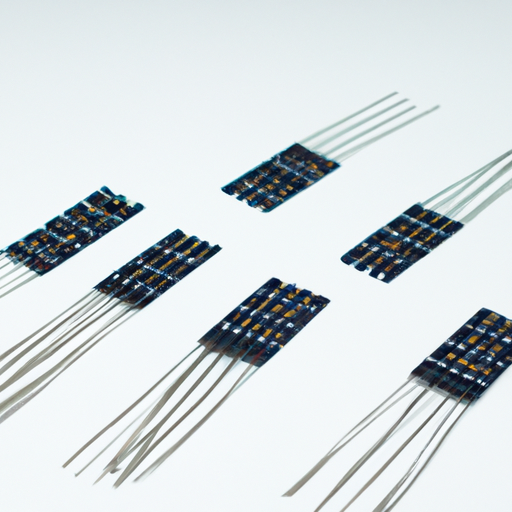

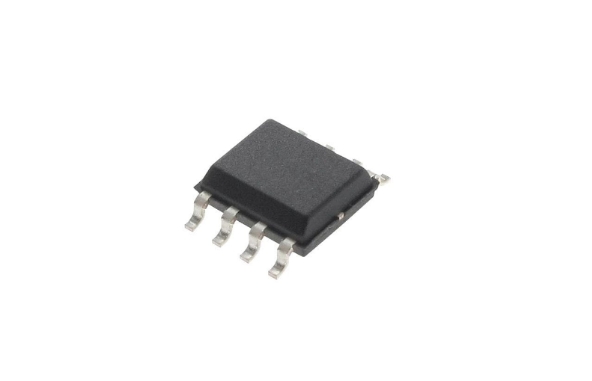

2. Thick Film Fuse Resistors

Thick film fuse resistors are made by applying a thick layer of resistive material onto a substrate. They are known for their compact size and are commonly used in surface-mount technology (SMT) applications. Their manufacturing process allows for high-volume production at a lower cost.

3. Thin Film Fuse Resistors

Thin film fuse resistors are created by depositing a thin layer of resistive material onto a substrate. They provide excellent performance in terms of precision and temperature stability. Thin film resistors are often used in high-frequency applications due to their low parasitic capacitance.

III. Regulatory Bodies and Standards

A. Overview of Key Regulatory Bodies

1. International Electrotechnical Commission (IEC)

The IEC is a global organization that develops and publishes international standards for electrical and electronic technologies. Their standards ensure safety, efficiency, and interoperability of electrical components, including fuse resistors.

2. Underwriters Laboratories (UL)

UL is a safety certification organization that tests and certifies products for safety and performance. Their standards are widely recognized in North America and are crucial for manufacturers looking to enter the U.S. market.

3. American National Standards Institute (ANSI)

ANSI oversees the development of voluntary consensus standards for products, services, and systems in the United States. Their standards help ensure that products meet specific safety and performance criteria.

4. European Committee for Electrotechnical Standardization (CENELEC)

CENELEC is responsible for standardization in the electrotechnical field in Europe. Their standards facilitate the free movement of goods within the European market and ensure safety and performance.

B. Importance of Compliance with Standards

Compliance with these standards is vital for manufacturers to ensure that their products are safe, reliable, and marketable. Non-compliance can lead to product recalls, legal liabilities, and damage to a company's reputation.

IV. Key Product Standards for Fuse Resistors

A. Electrical Characteristics

1. Resistance Value Tolerance

Resistance value tolerance specifies the allowable deviation from the nominal resistance value. This characteristic is crucial for ensuring that the fuse resistor performs as intended in a circuit.

2. Power Rating

The power rating indicates the maximum power the fuse resistor can dissipate without failing. It is essential for preventing overheating and ensuring the longevity of the component.

3. Voltage Rating

The voltage rating defines the maximum voltage that can be applied across the fuse resistor. Exceeding this rating can lead to breakdown and failure of the component.

B. Thermal Characteristics

1. Temperature Coefficient

The temperature coefficient measures how much the resistance value changes with temperature. A low temperature coefficient is desirable for maintaining consistent performance across varying temperatures.

2. Maximum Operating Temperature

The maximum operating temperature indicates the highest temperature at which the fuse resistor can function safely. Exceeding this temperature can lead to failure and potential hazards.

C. Mechanical Characteristics

1. Physical Dimensions

Physical dimensions are critical for ensuring that fuse resistors fit properly within a circuit design. Standardized dimensions help manufacturers produce components that are compatible with various applications.

2. Mounting and Packaging Standards

Mounting and packaging standards ensure that fuse resistors can be easily integrated into electronic devices. These standards cover aspects such as lead spacing, footprint, and packaging materials.

D. Safety Standards

1. Overload Protection

Overload protection standards ensure that fuse resistors can handle temporary overload conditions without failing. This characteristic is vital for protecting sensitive components in a circuit.

2. Short-Circuit Protection

Short-circuit protection standards define the ability of fuse resistors to interrupt current flow during a short circuit. This feature is essential for preventing damage to the circuit and ensuring safety.

3. Environmental Considerations

Environmental standards address the impact of fuse resistors on the environment, including considerations for materials used in manufacturing and end-of-life disposal.

V. Testing and Certification Processes

A. Overview of Testing Procedures

1. Electrical Testing

Electrical testing involves measuring the resistance, power rating, and voltage rating of fuse resistors to ensure they meet specified standards.

2. Thermal Testing

Thermal testing evaluates the thermal performance of fuse resistors, including their response to temperature changes and maximum operating temperature.

3. Mechanical Testing

Mechanical testing assesses the physical integrity of fuse resistors, including their resistance to mechanical stress and environmental factors.

B. Certification Process

1. Role of Third-Party Testing Labs

Third-party testing labs play a crucial role in the certification process by conducting independent tests to verify compliance with relevant standards.

2. Importance of Certification Marks

Certification marks indicate that a product has been tested and meets specific safety and performance standards. These marks provide assurance to consumers and manufacturers alike.

VI. Industry Applications of Fuse Resistors

A. Consumer Electronics

Fuse resistors are widely used in consumer electronics, such as televisions, computers, and smartphones, to protect sensitive components from overcurrent conditions.

B. Automotive Industry

In the automotive industry, fuse resistors are employed in various applications, including power management systems and safety features, to ensure reliable operation.

C. Industrial Equipment

Industrial equipment relies on fuse resistors for protection against overcurrent and short circuits, ensuring the safety and reliability of machinery.

D. Telecommunications

In telecommunications, fuse resistors are used to protect sensitive electronic components in devices such as routers, switches, and communication systems.

VII. Challenges and Considerations

A. Evolving Standards and Technologies

As technology advances, product standards for fuse resistors must evolve to address new challenges and applications. Manufacturers must stay informed about changes in standards to ensure compliance.

B. Importance of Continuous Compliance

Continuous compliance with product standards is essential for maintaining product quality and safety. Manufacturers must implement regular testing and quality control measures to ensure ongoing compliance.

C. Impact of Non-Compliance

Non-compliance with product standards can lead to serious consequences, including product recalls, legal liabilities, and damage to a company's reputation. It is crucial for manufacturers to prioritize compliance to avoid these risks.

VIII. Conclusion

A. Recap of the Importance of Standards

Product standards for fuse resistors are vital for ensuring safety, reliability, and performance in electrical circuits. Compliance with these standards protects consumers and industries alike.

B. Future Trends in Fuse Resistor Standards

As technology continues to advance, we can expect to see new trends in fuse resistor standards, including increased focus on environmental sustainability and the integration of smart technologies.

C. Final Thoughts on Compliance and Safety

Manufacturers must prioritize compliance with product standards to ensure the safety and reliability of their fuse resistors. By doing so, they can protect their customers and maintain a competitive edge in the market.

IX. References

A. List of Relevant Standards and Guidelines

1. IEC 60115 - Fixed Resistors for Use in Electronic Equipment

2. UL 1412 - Standard for Fuse Resistors

3. ANSI C63.4 - American National Standard for Methods of Measurement of Radio-Noise Emissions from Low-Voltage Electrical and Electronic Equipment in the Range of 9 kHz to 40 GHz

B. Suggested Further Reading on Fuse Resistors and Standards

1. "Understanding Fuse Resistors: A Comprehensive Guide" - Technical Paper

2. "The Role of Standards in Electrical Component Safety" - Industry Report

3. "Advancements in Fuse Resistor Technology" - Journal Article

This blog post provides a detailed overview of the product standards for fuse resistors, highlighting their importance in ensuring safety and reliability in various applications. By understanding these standards, manufacturers and consumers can make informed decisions regarding the use of fuse resistors in electrical circuits.