The Manufacturing Process of Resistors

I. Introduction

Resistors are fundamental components in electronic circuits, serving the crucial role of controlling the flow of electric current. By providing resistance, they help to regulate voltage and current levels, ensuring that electronic devices function correctly and safely. From simple household gadgets to complex industrial machinery, resistors are ubiquitous in modern electronics. This blog post will explore the manufacturing process of resistors, detailing the various types, raw materials, production techniques, and quality control measures involved in their creation.

II. Types of Resistors

Resistors come in various types, each designed for specific applications and performance characteristics. Understanding these types is essential for grasping the manufacturing process.

A. Fixed Resistors

Fixed resistors maintain a constant resistance value and are the most common type used in electronic circuits.

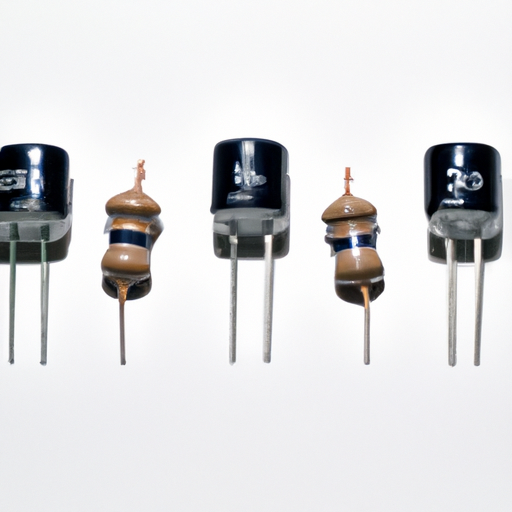

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and ability to withstand high temperatures.

2. **Film Resistors**: These include carbon film and metal film resistors, which are created by depositing a thin layer of resistive material onto a substrate. They offer better precision and stability compared to carbon composition resistors.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, these resistors are capable of handling high power levels and are often used in high-performance applications.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits.

1. **Potentiometers**: These are used to adjust voltage levels in circuits, commonly found in volume controls and other adjustable settings.

2. **Rheostats**: Similar to potentiometers but designed to handle higher currents, rheostats are often used in applications requiring variable resistance.

C. Specialty Resistors

Specialty resistors are designed for specific applications and include:

1. **Thermistors**: Temperature-sensitive resistors that change resistance with temperature variations, commonly used in temperature sensing and control.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these change resistance based on light exposure, making them useful in light-sensing applications.

III. Raw Materials

The manufacturing of resistors involves various raw materials, each contributing to the resistor's performance and characteristics.

A. Conductive Materials

1. **Carbon**: Used primarily in carbon composition and carbon film resistors, carbon provides a stable and reliable resistive element.

2. **Metal Oxides**: Commonly used in metal film resistors, metal oxides offer high stability and precision.

3. **Metal Wire**: Essential for wirewound resistors, metal wire (often made of nickel-chromium or copper) provides the necessary conductivity and resistance.

B. Insulating Materials

1. **Ceramic**: Used as a substrate for wirewound resistors, ceramic materials provide excellent thermal stability and insulation.

2. **Epoxy**: Often used for coating and encapsulating resistors, epoxy provides protection against environmental factors.

3. **Plastic**: Used in various resistor types for housing and insulation, plastic materials are lightweight and cost-effective.

IV. Manufacturing Process

The manufacturing process of resistors involves several key steps, from design to quality control.

A. Design and Specification

The first step in manufacturing resistors is determining the design specifications. This includes:

1. **Determining Resistance Value**: Engineers calculate the required resistance value based on the intended application.

2. **Tolerance and Power Rating**: Specifications for tolerance (the allowable deviation from the nominal resistance) and power rating (the maximum power the resistor can handle) are established.

B. Material Preparation

Once the design is finalized, the next step is material preparation:

1. **Sourcing Raw Materials**: Manufacturers procure high-quality raw materials from reliable suppliers to ensure consistent performance.

2. **Processing Materials**: This may involve grinding carbon into a fine powder, mixing it with binders, or preparing metal wires for winding.

C. Production Techniques

The production techniques vary depending on the type of resistor being manufactured.

1. **Carbon Composition Resistors**:

- **Mixing Carbon with a Binder**: The carbon powder is mixed with a binding agent to create a paste.

- **Molding and Curing**: The paste is molded into the desired shape and cured to harden the material.

2. **Film Resistors**:

- **Thin Film Process**:

- **Substrate Preparation**: A substrate (often ceramic) is cleaned and prepared for deposition.

- **Deposition of Resistive Material**: A thin layer of resistive material is deposited onto the substrate using techniques like sputtering or evaporation.

- **Etching and Trimming**: The deposited layer is etched to create the desired resistance pattern, followed by trimming to achieve precise resistance values.

- **Thick Film Process**:

- **Screen Printing**: A paste containing resistive material is screen-printed onto a substrate.

- **Firing and Curing**: The printed substrate is fired in a kiln to cure the resistive material, ensuring durability and stability.

3. **Wirewound Resistors**:

- **Winding Wire Around a Core**: A metal wire is wound around a ceramic or fiberglass core to create the resistive element.

- **Insulating and Coating**: The wound resistor is coated with insulating material to prevent short circuits and enhance durability.

D. Quality Control

Quality control is a critical aspect of resistor manufacturing, ensuring that each component meets the required specifications.

1. **Testing for Resistance Values**: Each resistor is tested to verify its resistance value against the specified tolerance.

2. **Checking for Physical Defects**: Visual inspections and automated systems are used to identify any physical defects, such as cracks or irregularities.

3. **Environmental Testing**: Resistors undergo environmental testing to assess their performance under various conditions, including temperature and humidity variations.

V. Packaging and Distribution

Once the resistors pass quality control, they are prepared for packaging and distribution.

A. Types of Packaging

1. **Bulk Packaging**: Resistors are often packaged in bulk for manufacturers who require large quantities.

2. **Tape and Reel**: For automated assembly processes, resistors are packaged in tape and reel formats, allowing for easy feeding into machines.

B. Shipping and Logistics

Efficient shipping and logistics are essential to ensure that resistors reach their destinations safely and on time. Manufacturers often work with logistics partners to streamline this process.

C. Importance of Proper Handling

Proper handling during packaging and shipping is crucial to prevent damage. Resistors are sensitive components, and any physical impact can affect their performance.

VI. Conclusion

The manufacturing process of resistors is a complex and meticulous endeavor that involves various stages, from design and material preparation to production and quality control. Resistors play a vital role in modern electronics, enabling devices to function correctly and efficiently. As technology advances, the demand for more precise and reliable resistors continues to grow, leading to innovations in manufacturing techniques and materials. Understanding the intricacies of resistor manufacturing not only highlights the importance of these components but also sheds light on the broader field of electronics and its ongoing evolution.

VII. References

For those interested in delving deeper into the topic of resistor manufacturing, the following resources are recommended:

1. "Electronic Components: A Complete Reference for Engineers and Technicians" by John L. Hennessy.

2. "Resistor Technology: A Comprehensive Guide" by David A. Johnson.

3. Online resources from electronics manufacturers and industry organizations, which often provide insights into the latest trends and technologies in resistor manufacturing.

By exploring these resources, readers can gain a more comprehensive understanding of the fascinating world of resistors and their manufacturing processes.