What is the Market Demand for Tool Chucks?

I. Introduction

A. Definition of Tool Chucks

Tool chucks are mechanical devices used to hold and secure tools in place during machining operations. They are essential components in various manufacturing processes, ensuring that tools remain stable and accurately positioned while cutting, drilling, or shaping materials. Tool chucks come in various designs and sizes, tailored to accommodate different types of tools and applications.

B. Importance of Tool Chucks in Manufacturing and Engineering

In the manufacturing and engineering sectors, precision and reliability are paramount. Tool chucks play a critical role in achieving these objectives by providing a secure grip on tools, which enhances accuracy and reduces the risk of tool slippage. This is particularly important in high-speed machining operations where even the slightest movement can lead to defects and increased production costs. As industries continue to evolve, the demand for high-quality tool chucks remains strong, driven by the need for efficiency and precision.

C. Overview of Market Demand

The market demand for tool chucks is influenced by various factors, including the growth of the manufacturing sector, advancements in technology, and the increasing need for customized solutions. This blog post will explore the different types of tool chucks, the current market landscape, driving factors, challenges, key players, and future outlook.

II. Types of Tool Chucks

A. Key Types of Tool Chucks

Tool chucks can be categorized into several types, each designed for specific applications:

1. **Drill Chucks**: These are used primarily in drilling machines and are designed to hold drill bits securely. They come in keyless and keyed varieties, allowing for easy tightening and loosening.

2. **Lathe Chucks**: Commonly used in lathes, these chucks hold workpieces in place during turning operations. They can be three-jaw or four-jaw chucks, with the former being more common for cylindrical workpieces.

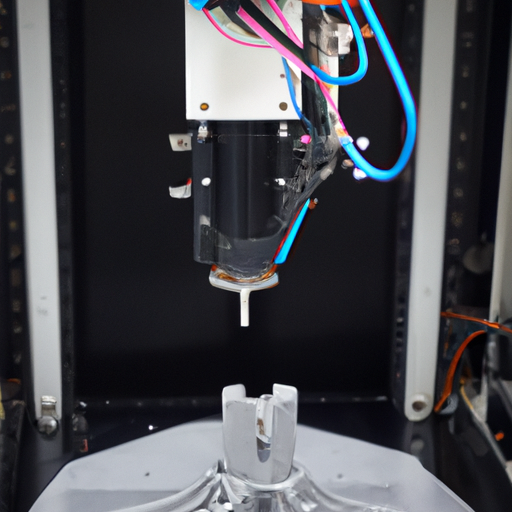

3. **Collet Chucks**: These chucks use a collet to grip the tool, providing a high level of precision. They are often used in CNC machines and are favored for their ability to hold tools with minimal runout.

4. **Magnetic Chucks**: These chucks use magnetic force to hold ferromagnetic workpieces in place. They are particularly useful in surface grinding applications.

B. Applications of Each Type

Each type of tool chuck has its specific applications. Drill chucks are essential in construction and woodworking, while lathe chucks are widely used in metalworking. Collet chucks are favored in precision machining, and magnetic chucks are commonly used in grinding and milling operations. Understanding the applications of each type helps manufacturers choose the right chuck for their needs.

C. Factors Influencing the Choice of Chuck Type

Several factors influence the choice of tool chuck, including the type of material being machined, the required precision, and the specific machining operation. Additionally, the size and weight of the workpiece, as well as the machine's capabilities, play a crucial role in determining the appropriate chuck type.

III. Market Overview

A. Global Market Size and Growth Rate

The global tool chuck market has experienced significant growth in recent years, driven by the expansion of the manufacturing sector and increasing automation. According to industry reports, the market is projected to grow at a compound annual growth rate (CAGR) of approximately 5% over the next five years, reaching a valuation of several billion dollars.

B. Key Regions Contributing to Market Demand

1. **North America**: The North American market is characterized by advanced manufacturing technologies and a strong presence of key players. The region's focus on automation and precision engineering drives demand for high-quality tool chucks.

2. **Europe**: Europe is home to several leading manufacturers and is known for its emphasis on innovation and sustainability. The region's automotive and aerospace industries significantly contribute to the demand for tool chucks.

3. **Asia-Pacific**: The Asia-Pacific region is witnessing rapid industrialization and urbanization, leading to increased manufacturing activities. Countries like China and India are major contributors to the growing demand for tool chucks.

4. **Latin America**: While still emerging, the Latin American market is gradually expanding, driven by investments in manufacturing and infrastructure development.

C. Market Trends and Innovations

The tool chuck market is witnessing several trends, including the integration of smart technologies and automation. Manufacturers are increasingly adopting IoT-enabled chucks that provide real-time monitoring and data analytics, enhancing operational efficiency. Additionally, there is a growing focus on sustainability, with manufacturers exploring eco-friendly materials and production processes.

IV. Factors Driving Market Demand

A. Growth of the Manufacturing Sector

The global manufacturing sector is experiencing robust growth, driven by increased demand for consumer goods, automotive components, and industrial machinery. As manufacturers seek to enhance productivity and reduce costs, the demand for reliable tool chucks continues to rise.

B. Advancements in Technology

1. Automation and Robotics

The rise of automation and robotics in manufacturing has significantly impacted the tool chuck market. Automated machining processes require precise and reliable tool holding solutions, leading to increased demand for advanced chucks that can withstand high speeds and loads.

2. Precision Engineering

As industries strive for higher precision and quality, the demand for tool chucks that offer minimal runout and enhanced gripping capabilities has surged. Precision engineering applications, such as aerospace and medical device manufacturing, are particularly reliant on high-quality tool chucks.

C. Increasing Demand for Customization

Manufacturers are increasingly seeking customized solutions to meet specific production requirements. This trend has led to a rise in demand for specialized tool chucks that can accommodate unique tool sizes and shapes, further driving market growth.

D. Rise of Small and Medium Enterprises (SMEs)

The growth of small and medium enterprises (SMEs) in the manufacturing sector has also contributed to the demand for tool chucks. SMEs often require versatile and cost-effective solutions, leading to increased sales of various chuck types.

V. Challenges Facing the Tool Chuck Market

A. Competition from Alternative Technologies

The tool chuck market faces competition from alternative technologies, such as tool holders and clamping systems. Manufacturers must continuously innovate to differentiate their products and maintain market share.

B. Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains, leading to disruptions in the availability of raw materials and components. These disruptions can impact production schedules and increase costs for manufacturers.

C. Economic Factors Affecting Manufacturing

Economic fluctuations, such as recessions or changes in trade policies, can significantly impact the manufacturing sector and, consequently, the demand for tool chucks. Manufacturers must remain agile to adapt to changing market conditions.

D. Environmental Regulations and Sustainability Concerns

As environmental regulations become more stringent, manufacturers are under pressure to adopt sustainable practices. This shift may require investments in new technologies and materials, impacting the overall cost structure of tool chuck production.

VI. Key Players in the Tool Chuck Market

A. Overview of Major Manufacturers

The tool chuck market is characterized by the presence of several key players, including:

Röhm GmbH: A leading manufacturer known for its innovative clamping technology and high-quality tool chucks.

Schunk GmbH: Renowned for its precision clamping solutions and extensive product range.

Bison Bial: A prominent player offering a wide variety of tool chucks and workholding solutions.

B. Market Share Analysis

Market share analysis reveals that a few major players dominate the tool chuck market, but there is also a growing presence of regional manufacturers catering to specific market needs. This competitive landscape encourages innovation and drives product development.

C. Strategic Initiatives and Collaborations

Key players in the tool chuck market are increasingly engaging in strategic initiatives, such as partnerships and collaborations, to enhance their product offerings and expand their market reach. These initiatives often focus on research and development to create advanced tool chuck solutions.

VII. Future Outlook

A. Predictions for Market Growth

The future outlook for the tool chuck market remains positive, with continued growth expected in the coming years. As manufacturing processes become more automated and precise, the demand for high-quality tool chucks will likely increase.

B. Emerging Technologies and Innovations

Emerging technologies, such as additive manufacturing and advanced materials, are expected to influence the tool chuck market. Manufacturers that embrace these innovations will be better positioned to meet evolving customer demands.

C. Potential Market Opportunities

The growing emphasis on sustainability presents opportunities for manufacturers to develop eco-friendly tool chucks and production processes. Additionally, the rise of Industry 4.0 and smart manufacturing will create demand for advanced tool holding solutions that integrate with digital systems.

VIII. Conclusion

A. Summary of Key Points

The market demand for tool chucks is driven by the growth of the manufacturing sector, advancements in technology, and the increasing need for customization. While challenges such as competition and supply chain disruptions exist, the overall outlook for the market remains positive.

B. Final Thoughts on Market Demand for Tool Chucks

As industries continue to evolve, the importance of tool chucks in ensuring precision and efficiency in manufacturing cannot be overstated. Stakeholders in the industry must stay informed about market trends and innovations to remain competitive.

C. Call to Action for Stakeholders in the Industry

Manufacturers, suppliers, and industry professionals should collaborate to drive innovation and address the challenges facing the tool chuck market. By embracing new technologies and sustainable practices, stakeholders can contribute to the growth and success of the industry.

IX. References

A comprehensive list of sources and further reading would be included here to support the information presented in the blog post.