What is the Manufacturing Process for Non-Standard Parts Processing?

I. Introduction

In the world of manufacturing, the term "non-standard parts" refers to components that do not conform to conventional specifications or dimensions. These parts are often custom-made to meet specific requirements of various industries, including aerospace, medical, and automotive sectors. The importance of non-standard parts cannot be overstated; they play a crucial role in the functionality and performance of complex systems. This blog post will provide an overview of the manufacturing process for non-standard parts, highlighting the stages involved, the challenges faced, and the future trends shaping this dynamic field.

II. Understanding Non-Standard Parts

A. Characteristics of Non-Standard Parts

Non-standard parts are characterized by their customization, unique specifications, and specialized applications. Unlike standard components that can be mass-produced, non-standard parts are tailored to meet the specific needs of a project or application. This customization often involves intricate designs and precise measurements, making them essential for high-performance applications.

B. Examples of Non-Standard Parts

1. **Aerospace Components**: In the aerospace industry, non-standard parts are critical for ensuring the safety and efficiency of aircraft. Components such as turbine blades, landing gear, and fuselage sections often require unique designs and materials to withstand extreme conditions.

2. **Medical Devices**: The medical field relies heavily on non-standard parts for devices such as prosthetics, surgical instruments, and diagnostic equipment. These components must meet stringent regulatory standards and be tailored to individual patient needs.

3. **Automotive Parts**: The automotive industry frequently utilizes non-standard parts for custom vehicles, performance upgrades, and specialized applications. Components like custom exhaust systems, suspension parts, and engine components are often designed to enhance performance and meet specific regulatory requirements.

III. The Manufacturing Process Overview

The manufacturing process for non-standard parts involves several key stages, each critical to ensuring the final product meets the required specifications.

A. Stages of Non-Standard Parts Manufacturing

1. **Design and Prototyping**: The first step in manufacturing non-standard parts is the design phase, where engineers create detailed specifications and prototypes.

2. **Material Selection**: Choosing the right materials is crucial for ensuring the part's performance and durability.

3. **Production Planning**: Effective planning is essential to streamline the manufacturing process and allocate resources efficiently.

4. **Machining and Fabrication**: This stage involves the actual production of the parts through various machining and fabrication techniques.

5. **Quality Control**: Ensuring the parts meet quality standards is vital for performance and safety.

6. **Finishing and Assembly**: After machining, parts undergo finishing processes and are assembled as needed.

7. **Delivery and Post-Production Support**: Finally, the parts are delivered to the client, and post-production support is provided as necessary.

IV. Design and Prototyping

A. Importance of Design in Non-Standard Parts

The design phase is critical in non-standard parts manufacturing. A well-thought-out design ensures that the part will function as intended and meet all necessary specifications. Engineers must consider factors such as load-bearing capacity, environmental conditions, and compatibility with other components.

B. Tools and Software Used in Design

1. **CAD (Computer-Aided Design)**: CAD software allows engineers to create detailed 2D and 3D models of parts, facilitating precise design and modifications.

2. **CAM (Computer-Aided Manufacturing)**: CAM software helps in planning and controlling the manufacturing processes, ensuring that the designs are accurately translated into physical parts.

C. Prototyping Techniques

1. **3D Printing**: This technique allows for rapid prototyping, enabling engineers to create physical models quickly for testing and evaluation.

2. **CNC Machining**: Computer Numerical Control (CNC) machining is used to produce prototypes with high precision, allowing for detailed testing before full-scale production.

3. **Rapid Prototyping**: This encompasses various techniques that enable quick production of prototypes, helping to speed up the design process.

V. Material Selection

A. Factors Influencing Material Choice

Selecting the right material for non-standard parts is crucial. Factors influencing this choice include:

1. **Mechanical Properties**: The material must possess the necessary strength, ductility, and hardness to withstand operational stresses.

2. **Environmental Resistance**: Depending on the application, materials may need to resist corrosion, temperature extremes, or other environmental factors.

3. **Cost Considerations**: Budget constraints often play a significant role in material selection, requiring a balance between performance and cost.

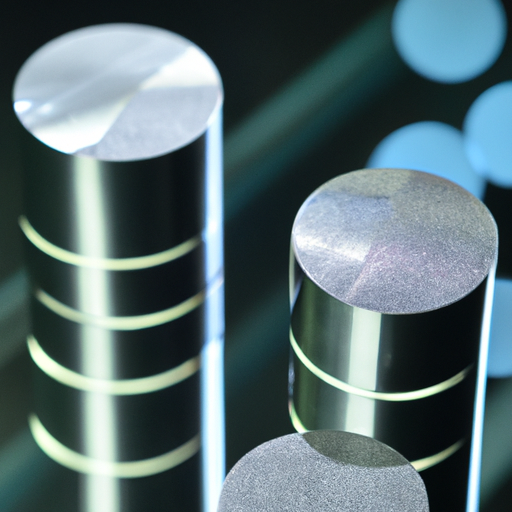

B. Common Materials Used for Non-Standard Parts

1. **Metals**: Aluminum, titanium, and steel are commonly used due to their strength and versatility.

2. **Plastics and Composites**: These materials are often chosen for their lightweight properties and resistance to corrosion.

3. **Specialty Alloys**: In high-performance applications, specialty alloys may be required to meet specific mechanical and thermal properties.

VI. Production Planning

A. Importance of Production Planning

Effective production planning is essential for ensuring that the manufacturing process runs smoothly and efficiently. It involves scheduling, resource allocation, and workflow management.

B. Techniques for Effective Planning

1. **Lean Manufacturing Principles**: These principles focus on minimizing waste and maximizing efficiency throughout the production process.

2. **Just-In-Time (JIT) Production**: JIT production aims to reduce inventory costs by producing parts only as needed, aligning production with demand.

C. Resource Allocation and Scheduling

Proper resource allocation and scheduling are critical to meeting deadlines and ensuring that all necessary materials and equipment are available when needed.

VII. Machining and Fabrication

A. Overview of Machining Processes

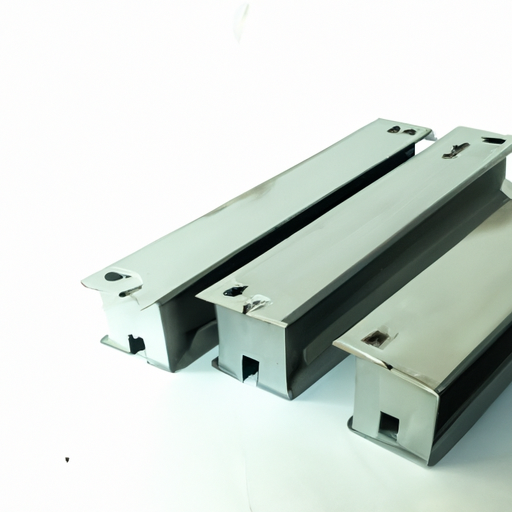

1. **CNC Machining**: This process uses computer-controlled machines to produce parts with high precision, making it ideal for non-standard components.

2. **Turning and Milling**: These traditional machining processes are used to shape materials into the desired form.

3. **Electrical Discharge Machining (EDM)**: EDM is used for creating complex shapes and features in hard materials.

B. Fabrication Techniques

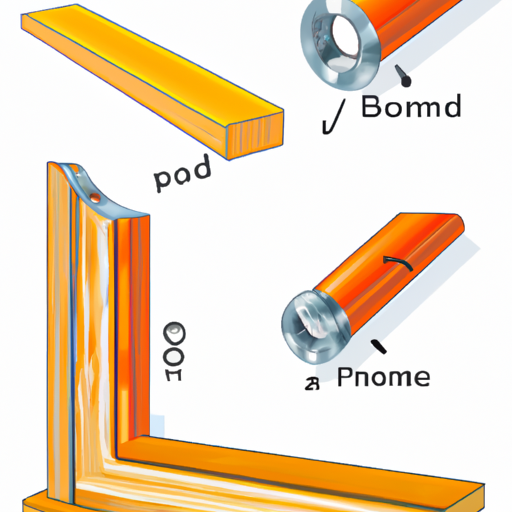

1. **Welding**: This technique is often used to join metal parts together, creating strong and durable assemblies.

2. **Sheet Metal Fabrication**: This process involves cutting, bending, and assembling sheet metal into various shapes.

3. **Additive Manufacturing**: Also known as 3D printing, this technique allows for the creation of complex geometries that would be difficult or impossible to achieve with traditional methods.

VIII. Quality Control

A. Importance of Quality Control in Non-Standard Parts

Quality control is vital in non-standard parts manufacturing to ensure that each component meets the required specifications and standards. This is especially important in industries where safety and performance are critical.

B. Quality Assurance Techniques

1. **Inspection Methods**: Various inspection methods, including visual inspections and dimensional checks, are used to verify the quality of parts.

2. **Testing Procedures**: Parts may undergo various tests, such as stress testing and fatigue testing, to ensure they can withstand operational conditions.

C. Certifications and Standards

1. **ISO Standards**: Adhering to ISO standards ensures that manufacturing processes meet international quality benchmarks.

2. **Industry-Specific Certifications**: Many industries have specific certifications that must be met, such as AS9100 for aerospace or ISO 13485 for medical devices.

IX. Finishing and Assembly

A. Finishing Techniques

1. **Surface Treatment**: Techniques such as anodizing, painting, or polishing are used to enhance the surface properties of parts.

2. **Coating and Plating**: These processes provide additional protection against corrosion and wear.

B. Assembly Processes

1. **Manual vs. Automated Assembly**: Depending on the complexity and volume of production, parts may be assembled manually or through automated processes.

2. **Importance of Tolerance and Fit**: Ensuring proper tolerances and fits is crucial for the functionality of assembled parts.

X. Delivery and Post-Production Support

A. Logistics and Delivery Considerations

Efficient logistics and delivery processes are essential for ensuring that non-standard parts reach clients on time and in good condition.

B. Post-Production Services

1. **Maintenance and Repair**: Providing maintenance and repair services can enhance customer satisfaction and extend the life of the parts.

2. **Customer Support**: Offering robust customer support helps address any issues that may arise after delivery.

XI. Challenges in Non-Standard Parts Manufacturing

A. Complexity of Design and Production

The intricate designs and specifications of non-standard parts can lead to challenges in both the design and production phases.

B. Cost Management

Managing costs while maintaining quality can be a significant challenge, especially in industries with tight margins.

C. Meeting Regulatory Requirements

Compliance with industry regulations and standards is essential, adding another layer of complexity to the manufacturing process.

XII. Future Trends in Non-Standard Parts Manufacturing

A. Advances in Technology

1. **Automation and Robotics**: The integration of automation and robotics is streamlining production processes and improving efficiency.

2. **Smart Manufacturing**: The use of IoT and data analytics is enabling manufacturers to optimize processes and enhance decision-making.

B. Sustainability Considerations

As industries move towards more sustainable practices, the manufacturing of non-standard parts is also evolving to incorporate eco-friendly materials and processes.

C. Customization and Mass Customization

The demand for customization is growing, leading to innovations in mass customization techniques that allow for efficient production of tailored parts.

XIII. Conclusion

In conclusion, non-standard parts play a vital role in various industries, and their manufacturing process is complex and multifaceted. From design and prototyping to material selection and quality control, each stage is crucial for ensuring that the final product meets the required specifications. As technology continues to advance, the future of non-standard parts processing looks promising, with opportunities for increased efficiency, customization, and sustainability. Understanding this manufacturing process is essential for anyone involved in industries that rely on these critical components.