How to Choose an Off-the-Shelf Nitrogen Gas Spring

I. Introduction

In the world of mechanical engineering and design, the selection of components can significantly impact the performance and efficiency of a system. One such component that plays a crucial role in various applications is the nitrogen gas spring. These springs are essential for providing controlled force and motion in a wide range of machinery and products. This article aims to guide you through the process of choosing the right off-the-shelf nitrogen gas spring, ensuring that you make an informed decision that meets your specific needs.

II. Understanding Nitrogen Gas Springs

A. What is a Nitrogen Gas Spring?

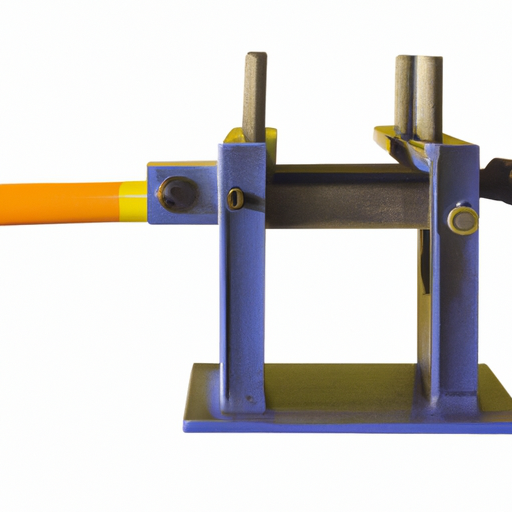

A nitrogen gas spring is a type of spring that utilizes compressed nitrogen gas to provide a force that can be used to lift, lower, or hold loads. The basic components of a nitrogen gas spring include a cylinder, a piston, and a gas charge. When the piston is compressed, the nitrogen gas inside the cylinder is compressed, storing energy that can be released to perform work.

B. Applications of Nitrogen Gas Springs

Nitrogen gas springs are versatile and find applications in various industries:

1. **Industrial Machinery**: They are commonly used in manufacturing equipment, such as presses and stamping machines, to provide consistent force and support during operations.

2. **Automotive Applications**: In the automotive industry, nitrogen gas springs are used in hoods, trunks, and tailgates to assist in opening and closing mechanisms.

3. **Furniture and Consumer Products**: Many modern furniture designs incorporate nitrogen gas springs for adjustable seating and lifting mechanisms, enhancing user comfort and convenience.

III. Key Factors to Consider When Choosing a Nitrogen Gas Spring

When selecting a nitrogen gas spring, several key factors must be considered to ensure optimal performance.

A. Load Capacity

Understanding the load requirements is crucial. The load capacity of a nitrogen gas spring refers to the maximum weight it can support. To calculate the necessary force, consider the weight of the object being lifted or supported and any additional dynamic forces that may occur during operation.

B. Stroke Length

Stroke length is the distance the piston travels when the spring is compressed or extended. It is essential to measure the stroke length accurately, as it directly affects the spring's ability to perform its intended function. To measure stroke length, determine the distance between the fully compressed and fully extended positions of the spring.

C. Operating Temperature Range

The performance of nitrogen gas springs can be affected by temperature. It is essential to select springs that can operate effectively within the specific temperature range of your application. Extreme temperatures can impact the gas pressure and, consequently, the spring's performance.

D. Mounting Options

Different applications may require various mounting configurations. Understanding the types of mounting options available and ensuring compatibility with existing systems is vital for seamless integration. Common mounting options include eyelet mounts, clevis mounts, and flange mounts.

E. Material and Construction

The materials used in the construction of nitrogen gas springs can significantly impact their durability and performance. Common materials include steel and aluminum, which offer different levels of strength and corrosion resistance. Consider the environment in which the spring will operate to select the most suitable material.

F. Preload and Pressure Settings

Preload refers to the initial compression of the spring before any external load is applied. Understanding preload is essential for achieving the desired performance. Additionally, pressure settings play a critical role in the spring's functionality, as they determine the force exerted by the spring.

IV. Performance Characteristics

A. Response Time

In dynamic applications, response time is crucial. It refers to how quickly the spring can react to changes in load or position. Factors affecting response time include the design of the spring, the viscosity of the gas, and the overall system configuration.

B. Cycle Life

Cycle life refers to the number of times a nitrogen gas spring can be compressed and extended before failure. It is essential to assess the cycle life to ensure that the spring can withstand the demands of your application over time.

C. Damping Characteristics

Damping is the ability of a spring to absorb energy and reduce oscillations. In applications where smooth motion is critical, consider springs with adjustable damping options to fine-tune performance.

V. Sourcing Off-the-Shelf Nitrogen Gas Springs

A. Reputable Manufacturers and Suppliers

When sourcing nitrogen gas springs, it is essential to choose reputable manufacturers and suppliers. Look for companies with a proven track record in the industry and those that adhere to relevant certifications and standards. This ensures that you receive high-quality products that meet safety and performance requirements.

B. Customization vs. Off-the-Shelf Options

While off-the-shelf nitrogen gas springs are readily available and often cost-effective, there may be instances where customization is necessary. Consider customization when your application has unique requirements that standard springs cannot meet. However, off-the-shelf solutions are typically faster to obtain and can be a practical choice for many applications.

VI. Testing and Validation

A. Importance of Testing Selected Springs

Once you have selected a nitrogen gas spring, it is crucial to test its performance to ensure it meets your specifications. Testing helps identify any potential issues before the spring is integrated into your system.

B. Methods for Validating Performance

1. **Load Testing**: This involves applying the expected load to the spring and measuring its performance to ensure it operates within the desired parameters.

2. **Environmental Testing**: Assessing how the spring performs under various environmental conditions, such as temperature and humidity, is essential for applications in challenging environments.

C. Adjustments and Fine-Tuning

After testing, you may need to make adjustments to the spring's preload or pressure settings to optimize performance. Fine-tuning ensures that the spring operates efficiently and effectively in your specific application.

VII. Conclusion

Choosing the right off-the-shelf nitrogen gas spring is a critical decision that can significantly impact the performance of your machinery or product. By considering key factors such as load capacity, stroke length, operating temperature range, and material construction, you can make an informed choice that meets your specific needs. Additionally, sourcing from reputable manufacturers and conducting thorough testing will ensure that the selected spring performs reliably over time. When in doubt, consulting with experts in the field can provide valuable insights and guidance.

VIII. References

- Suggested readings and resources on nitrogen gas springs and their applications.

- Industry standards and guidelines for selecting and testing gas springs.

By following this comprehensive guide, you can confidently navigate the process of selecting an off-the-shelf nitrogen gas spring, ensuring optimal performance and reliability in your applications.