How to Choose Ready-Made Flat Wire Springs

Introduction

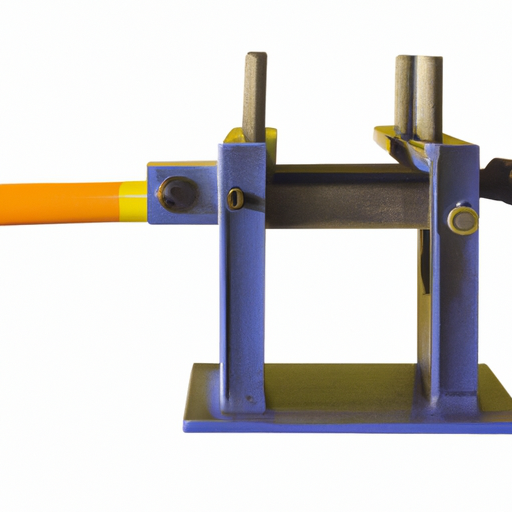

Flat wire springs are essential components in various mechanical systems, providing the necessary force and flexibility for a wide range of applications. These springs are characterized by their flat, ribbon-like shape, which allows them to be used in confined spaces where traditional round wire springs may not fit. Selecting the right flat wire spring is crucial for ensuring optimal performance, safety, and longevity in your projects. This article aims to guide you through the process of choosing ready-made flat wire springs, covering everything from understanding their types and applications to key factors to consider and common mistakes to avoid.

1. Understanding Flat Wire Springs

1.1 What are Flat Wire Springs?

Flat wire springs are mechanical devices made from flat strips of metal that are designed to store and release energy. They are typically manufactured from materials such as stainless steel, carbon steel, and other alloys, which provide the necessary strength and flexibility. The unique shape of flat wire springs allows them to be used in applications where space is limited, making them a popular choice in various industries.

1.2 Types of Flat Wire Springs

Flat wire springs come in several types, each designed for specific functions:

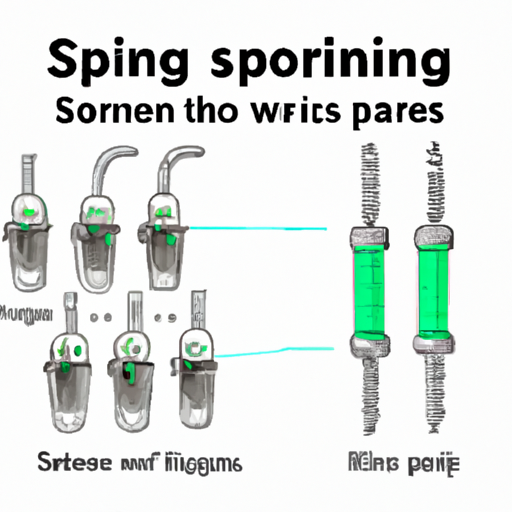

Compression Springs: These springs are designed to resist compressive forces. They are commonly used in applications where space is limited, such as in automotive suspensions and electronic devices.

Tension Springs: Tension springs are designed to absorb and store energy when stretched. They are often used in applications like door mechanisms and safety devices.

Torsion Springs: These springs are designed to provide rotational force. They are commonly found in applications such as clothespins and various mechanical devices.

Specialty Springs: This category includes leaf springs and flat spiral springs, which are designed for specific applications, such as automotive suspensions and compact mechanisms.

2. Applications of Flat Wire Springs

2.1 Industrial Applications

Flat wire springs play a vital role in various industrial applications. They are commonly used in machinery and equipment, providing the necessary force to operate moving parts. In the automotive and aerospace industries, flat wire springs are essential for ensuring the reliability and safety of vehicles and aircraft.

2.2 Consumer Products

In consumer products, flat wire springs can be found in household items such as appliances, toys, and electronics. They are crucial for the functionality of safety mechanisms, ensuring that devices operate smoothly and safely.

2.3 Medical Devices

Flat wire springs are also used in medical devices, where specific requirements must be met. These applications often require springs that can withstand sterilization processes and comply with regulatory standards. Understanding these requirements is essential for ensuring the safety and effectiveness of medical devices.

3. Key Factors to Consider When Choosing Flat Wire Springs

3.1 Material Selection

The material used to manufacture flat wire springs significantly impacts their performance. Key properties to consider include strength, corrosion resistance, and fatigue life. Common materials include:

Stainless Steel: Known for its excellent corrosion resistance, making it suitable for applications exposed to moisture or chemicals.

Carbon Steel: Offers high strength and is often used in applications where cost is a concern, but it may require additional coatings for corrosion resistance.

Alloy Steels: These materials provide enhanced strength and fatigue resistance, making them ideal for high-stress applications.

3.2 Dimensions and Specifications

Understanding the dimensions and specifications of flat wire springs is crucial for ensuring proper fit and function. Key dimensions to consider include:

Wire Diameter: Affects the spring's strength and flexibility.

Width: Determines the spring's load-bearing capacity.

Length: Impacts the spring's overall performance and fit within the application.

Additionally, tolerances and clearances must be considered to ensure that the spring operates effectively within its designated space.

3.3 Load Requirements

Calculating the load requirements is essential for selecting the right flat wire spring. This involves understanding both static and dynamic loads:

Static Loads: These are constant forces applied to the spring, such as the weight of an object.

Dynamic Loads: These are variable forces that occur during operation, such as vibrations or impacts.

Understanding the load capacity and deflection characteristics of the spring will help ensure that it meets the demands of the application.

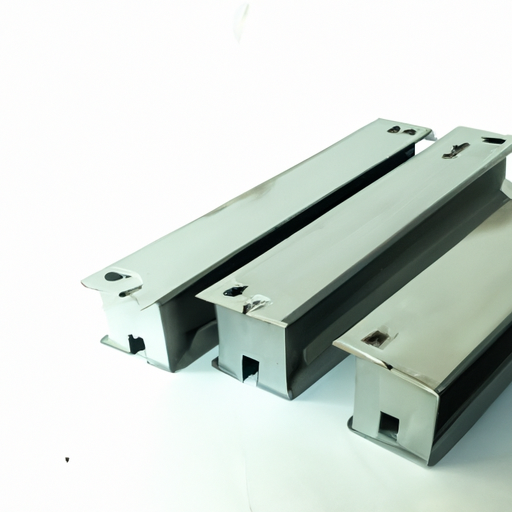

3.4 Spring Design and Configuration

The design and configuration of flat wire springs can vary significantly based on their intended use. Key design considerations include:

Shape: The overall shape of the spring can affect its performance and fit within the application.

Coil Count: The number of coils can influence the spring's flexibility and load capacity.

Custom vs. Standard Designs: While standard designs may be suitable for many applications, custom designs may be necessary for specialized needs.

3.5 Environmental Considerations

Environmental factors can significantly impact the performance and longevity of flat wire springs. Considerations include:

Temperature: Extreme temperatures can affect the material properties of the spring.

Humidity: High humidity levels can lead to corrosion, especially in materials that are not corrosion-resistant.

Chemical Exposure: Springs exposed to harsh chemicals may require special coatings or materials to prevent degradation.

Selecting springs that are suitable for the specific environmental conditions will help ensure their reliability and performance.

4. Sourcing Ready-Made Flat Wire Springs

4.1 Finding Reliable Suppliers

When sourcing ready-made flat wire springs, it is essential to find reliable suppliers. Key criteria for evaluating suppliers include:

Reputation: Look for suppliers with a proven track record in the industry.

Certifications: Ensure that the supplier meets relevant industry standards, such as ISO or ASTM certifications.

Customer Service: Good customer service and support can make a significant difference in the sourcing process.

4.2 Understanding Pricing and Lead Times

Pricing for flat wire springs can vary based on several factors, including:

Material: The choice of material can significantly impact the cost.

Complexity: More complex designs may require additional manufacturing processes, increasing the price.

Volume: Bulk orders may qualify for discounts, while smaller orders may incur higher per-unit costs.

Understanding lead times is also crucial for project planning. Ensure that the supplier can meet your timeline to avoid delays in your project.

4.3 Quality Assurance and Testing

Quality assurance is vital when sourcing flat wire springs. Look for suppliers that have robust quality control processes in place. Certifications such as ISO and ASTM can provide assurance of the spring's quality and performance. Additionally, inquire about testing procedures to ensure that the springs meet the required specifications.

5. Common Mistakes to Avoid

5.1 Overlooking Specifications

One of the most common mistakes when selecting flat wire springs is overlooking detailed specifications. Ensure that you have a clear understanding of the required dimensions, load capacities, and material properties before making a selection.

5.2 Ignoring Environmental Factors

Neglecting environmental considerations can lead to premature failure of the springs. Always consider the operating environment and select materials and designs that can withstand the conditions.

5.3 Failing to Test and Validate

Prototype testing and validation are crucial steps in the selection process. Failing to test the springs in real-world conditions can lead to unexpected failures and costly rework.

6. Conclusion

Choosing the right ready-made flat wire springs is a critical step in ensuring the success of your projects. By understanding the types of springs available, their applications, and the key factors to consider, you can make informed decisions that enhance performance and reliability. Remember to consult with experts when in doubt, and always prioritize quality and specifications to avoid common pitfalls.

7. Additional Resources

For further reading and resources on flat wire springs, consider the following:

Books and Articles: Look for industry-specific literature that covers spring design and applications.

Industry Standards: Familiarize yourself with relevant standards such as ISO and ASTM for quality assurance.

Professional Consultation: Reach out to experts in the field for personalized advice and guidance on your specific needs.

By leveraging these resources, you can enhance your understanding and ensure that you make the best choices for your flat wire spring applications.