Common Types of High Voltage Resistors

I. Introduction

High voltage resistors are essential components in various electrical and electronic applications, designed to operate safely and effectively in high voltage environments. These resistors are crucial for managing electrical energy, ensuring stability, and protecting sensitive components from voltage spikes. In this article, we will explore the different types of high voltage resistors, their characteristics, applications, and factors to consider when selecting the right resistor for your needs.

II. Understanding High Voltage Resistors

A. What Constitutes a High Voltage Resistor?

High voltage resistors are defined by their ability to handle voltages significantly higher than standard resistors. Typically, a resistor is considered high voltage if it can operate at voltages above 1,000 volts. These resistors are used in applications where high voltage levels are present, such as power supplies, testing equipment, and telecommunications.

B. Key Characteristics of High Voltage Resistors

When selecting high voltage resistors, several key characteristics must be considered:

1. **Power Rating**: This indicates the maximum power the resistor can dissipate without overheating. High voltage resistors often have higher power ratings to accommodate the energy levels they encounter.

2. **Tolerance**: This refers to the precision of the resistor's value. High voltage applications often require resistors with tight tolerances to ensure accurate performance.

3. **Temperature Coefficient**: This characteristic indicates how much the resistance value changes with temperature. A low temperature coefficient is desirable in high voltage applications to maintain stability across varying environmental conditions.

III. Types of High Voltage Resistors

High voltage resistors come in various types, each with unique construction, advantages, disadvantages, and applications. Here, we will discuss the most common types:

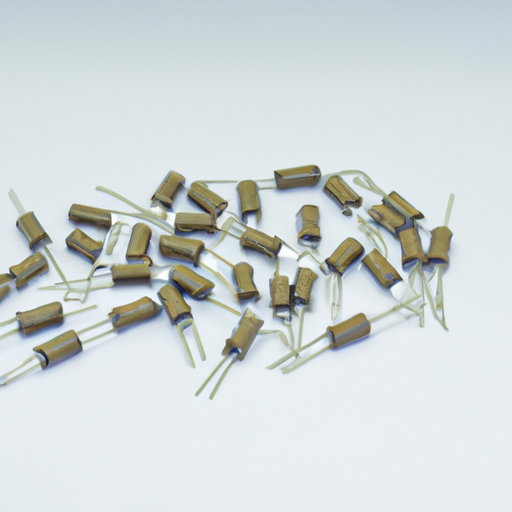

A. Carbon Composition Resistors

**1. Construction and Materials**: Carbon composition resistors are made from a mixture of carbon particles and a binding resin. The resistance value is determined by the ratio of carbon to resin.

**2. Advantages and Disadvantages**: These resistors are known for their high energy absorption capability and ability to withstand high voltage spikes. However, they have a relatively high temperature coefficient and lower stability over time compared to other types.

**3. Typical Applications**: Carbon composition resistors are often used in high voltage applications such as power amplifiers and audio equipment.

B. Metal Film Resistors

**1. Construction and Materials**: Metal film resistors are made by depositing a thin layer of metal onto a ceramic substrate. The resistance value is adjusted by cutting a spiral groove into the metal film.

**2. Advantages and Disadvantages**: These resistors offer excellent stability, low noise, and tight tolerances. However, they may not handle high power levels as effectively as wirewound resistors.

**3. Typical Applications**: Metal film resistors are commonly used in precision applications, including instrumentation and measurement devices.

C. Wirewound Resistors

**1. Construction and Materials**: Wirewound resistors consist of a wire (usually made of nickel-chromium alloy) wound around a ceramic or fiberglass core.

**2. Advantages and Disadvantages**: They can handle high power levels and have excellent heat dissipation properties. However, they can be bulkier and more expensive than other types.

**3. Typical Applications**: Wirewound resistors are often used in power supplies, motor control circuits, and high voltage testing equipment.

D. Thick Film Resistors

**1. Construction and Materials**: Thick film resistors are made by printing a thick layer of resistive material onto a substrate, typically ceramic.

**2. Advantages and Disadvantages**: They are cost-effective and can be produced in various shapes and sizes. However, they may have higher noise levels and lower precision compared to thin film resistors.

**3. Typical Applications**: Thick film resistors are widely used in consumer electronics and automotive applications.

E. Thin Film Resistors

**1. Construction and Materials**: Thin film resistors are created by depositing a very thin layer of resistive material onto a substrate.

**2. Advantages and Disadvantages**: They offer high precision, low noise, and excellent temperature stability. However, they can be more expensive and less robust than thick film resistors.

**3. Typical Applications**: Thin film resistors are used in high-end applications such as medical devices and precision measurement equipment.

F. High Voltage Resistor Networks

**1. Definition and Construction**: High voltage resistor networks consist of multiple resistors connected in series or parallel to achieve a desired resistance value and voltage rating.

**2. Advantages and Disadvantages**: These networks can provide better performance in terms of power handling and voltage division. However, they can be more complex to design and implement.

**3. Typical Applications**: High voltage resistor networks are commonly used in voltage dividers and high voltage testing equipment.

G. Specialty High Voltage Resistors

**1. Overview of Custom and Specialized Resistors**: Specialty high voltage resistors are designed for specific applications that require unique characteristics, such as high precision or extreme environmental resistance.

**2. Applications in Niche Markets**: These resistors are often used in aerospace, military, and medical applications where standard resistors may not meet the stringent requirements.

IV. Factors to Consider When Choosing High Voltage Resistors

When selecting high voltage resistors, several factors should be taken into account:

A. Voltage Rating and Power Handling

Ensure that the resistor can handle the maximum voltage and power levels expected in your application. Exceeding these ratings can lead to failure and potential hazards.

B. Environmental Considerations

Consider the operating environment, including temperature, humidity, and exposure to chemicals. Some resistors are better suited for harsh conditions than others.

C. Application-Specific Requirements

Different applications may have unique requirements, such as size constraints, precision, or noise levels. Choose a resistor that meets these specific needs.

D. Cost vs. Performance Analysis

Evaluate the trade-offs between cost and performance. While high precision and stability may be desirable, they often come at a higher price. Determine the best balance for your application.

V. Applications of High Voltage Resistors

High voltage resistors are used in a variety of applications, including:

A. Power Supplies

In power supply circuits, high voltage resistors help regulate voltage levels and protect sensitive components from voltage spikes.

B. Voltage Dividers

High voltage resistors are essential in voltage divider circuits, allowing for the safe measurement of high voltages by reducing them to a manageable level.

C. High Voltage Testing Equipment

Testing equipment for high voltage applications relies on high voltage resistors to ensure accurate measurements and safe operation.

D. Medical Devices

In medical devices, high voltage resistors are used to ensure the safe operation of equipment such as defibrillators and imaging systems.

E. Telecommunications

High voltage resistors play a critical role in telecommunications equipment, helping to manage signal integrity and protect against voltage surges.

VI. Conclusion

High voltage resistors are vital components in many electrical and electronic applications, providing stability and protection in high voltage environments. Understanding the different types of high voltage resistors, their characteristics, and their applications is essential for selecting the right resistor for your needs. As technology continues to evolve, we can expect advancements in high voltage resistor technology, leading to improved performance and new applications in various industries.

VII. References

For further exploration of high voltage resistors, consider the following resources:

1. "Resistor Technology: A Comprehensive Guide" - A detailed overview of resistor types and applications.

2. "High Voltage Engineering" - A textbook covering the principles and practices of high voltage technology.

3. Industry standards such as IEC 60115 and MIL-PRF-39007, which provide guidelines for resistor performance and testing.

By understanding the common types of high voltage resistors and their applications, engineers and designers can make informed decisions that enhance the safety and performance of their electrical systems.