Information

dict2_description

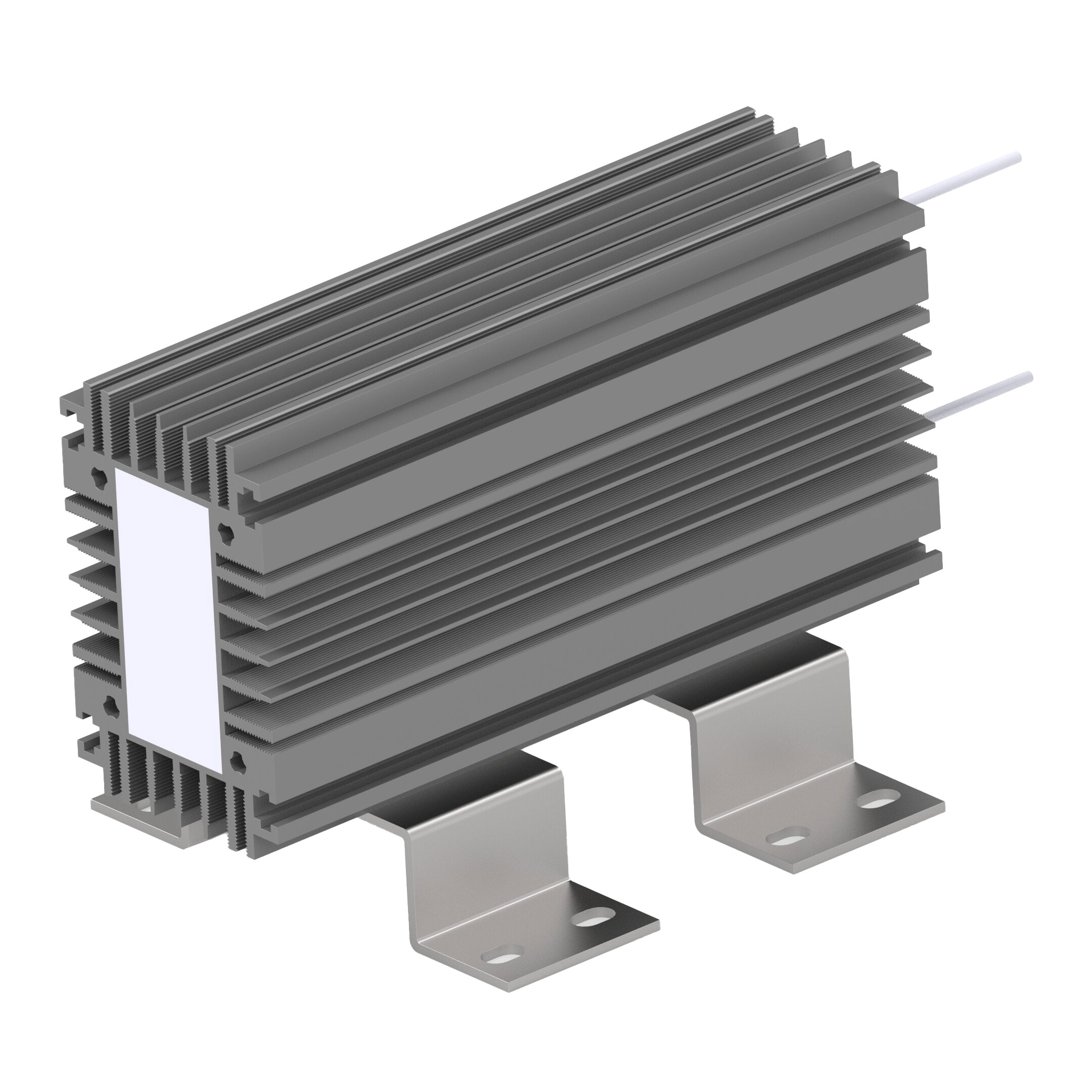

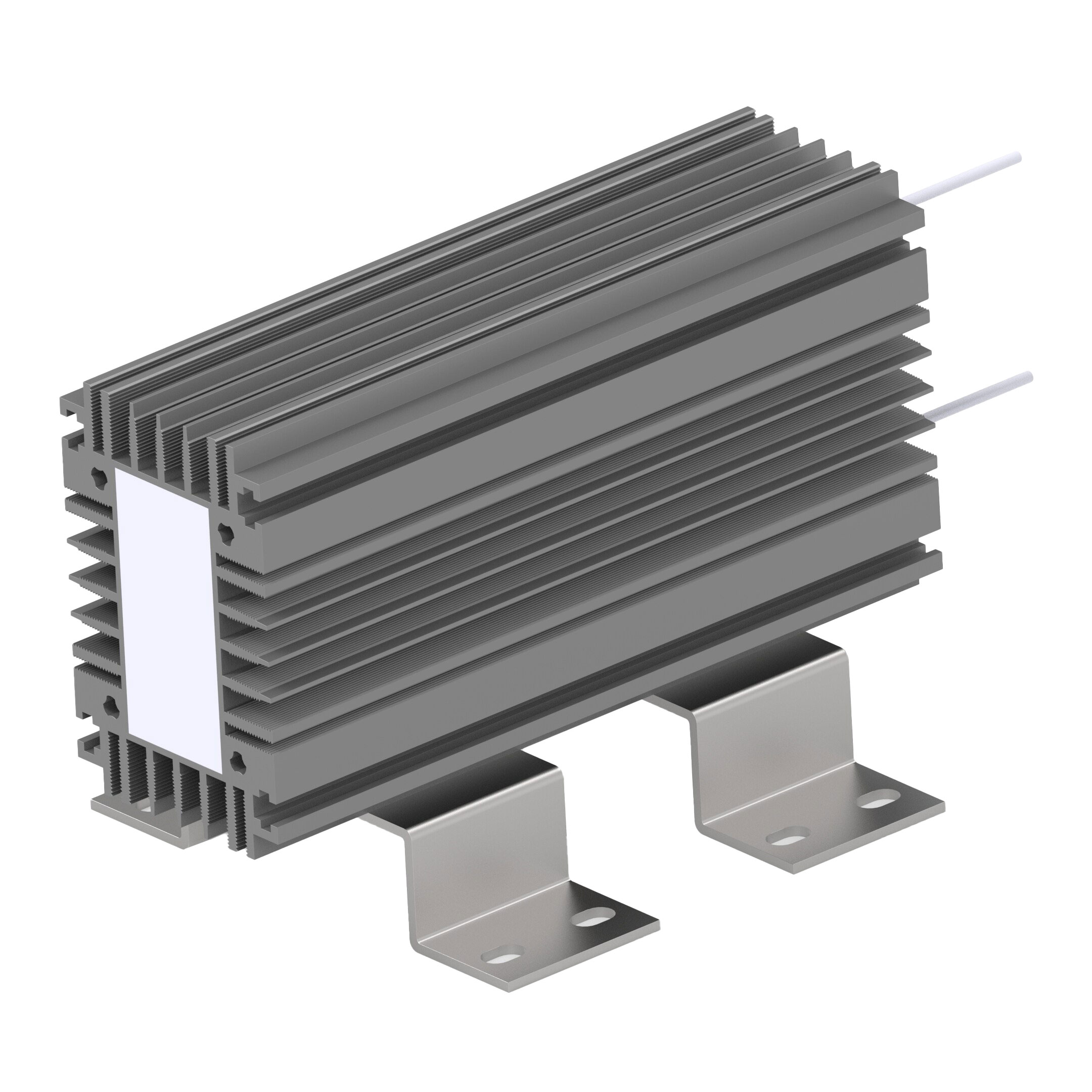

What are the advantages of resistor products?

2024-11-25

1

dict3_title

dict3_description