Information

dict2_description

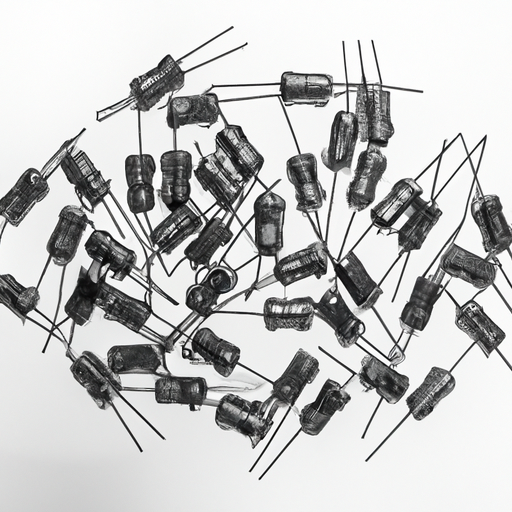

What is the manufacturing process of resistors?

2024-12-11

0

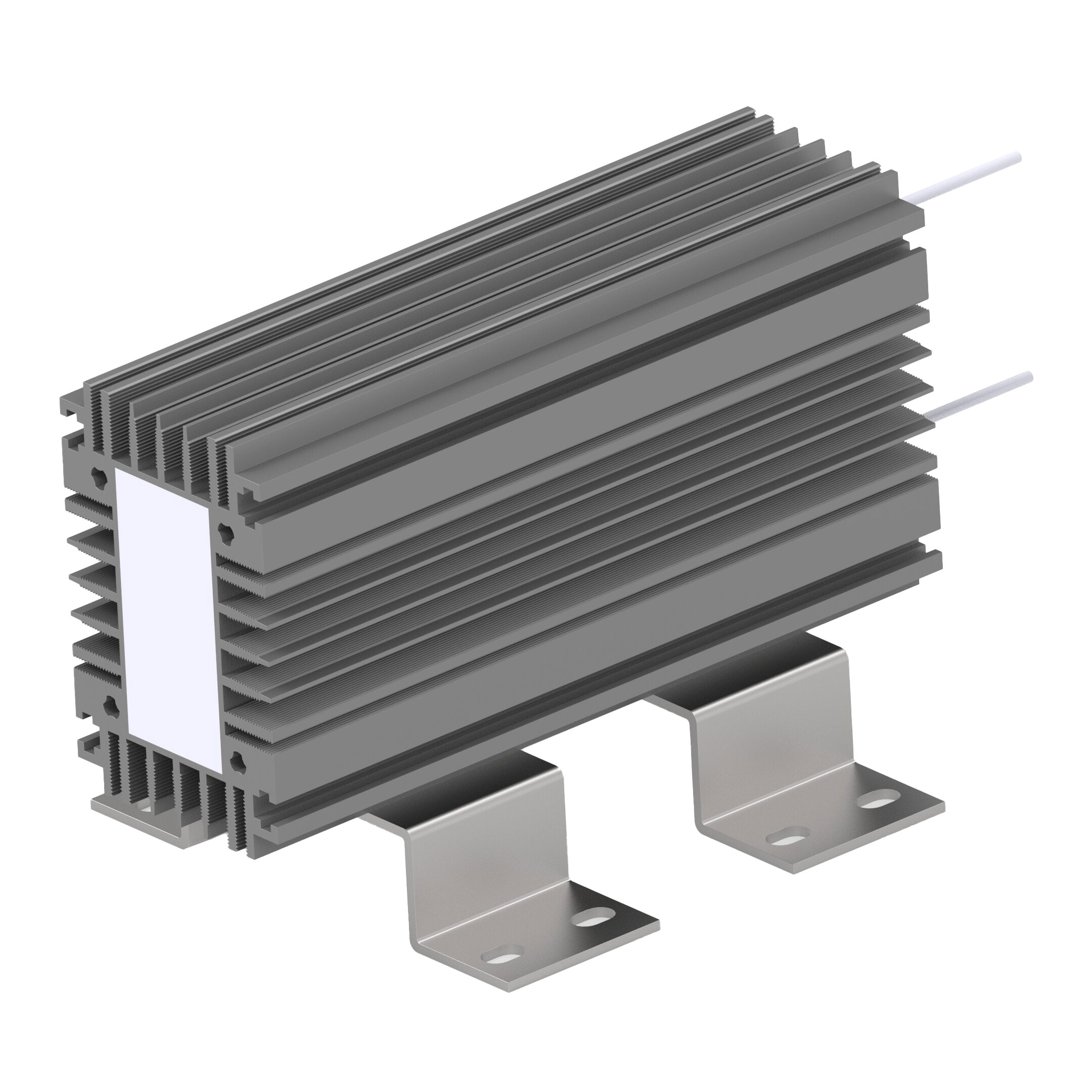

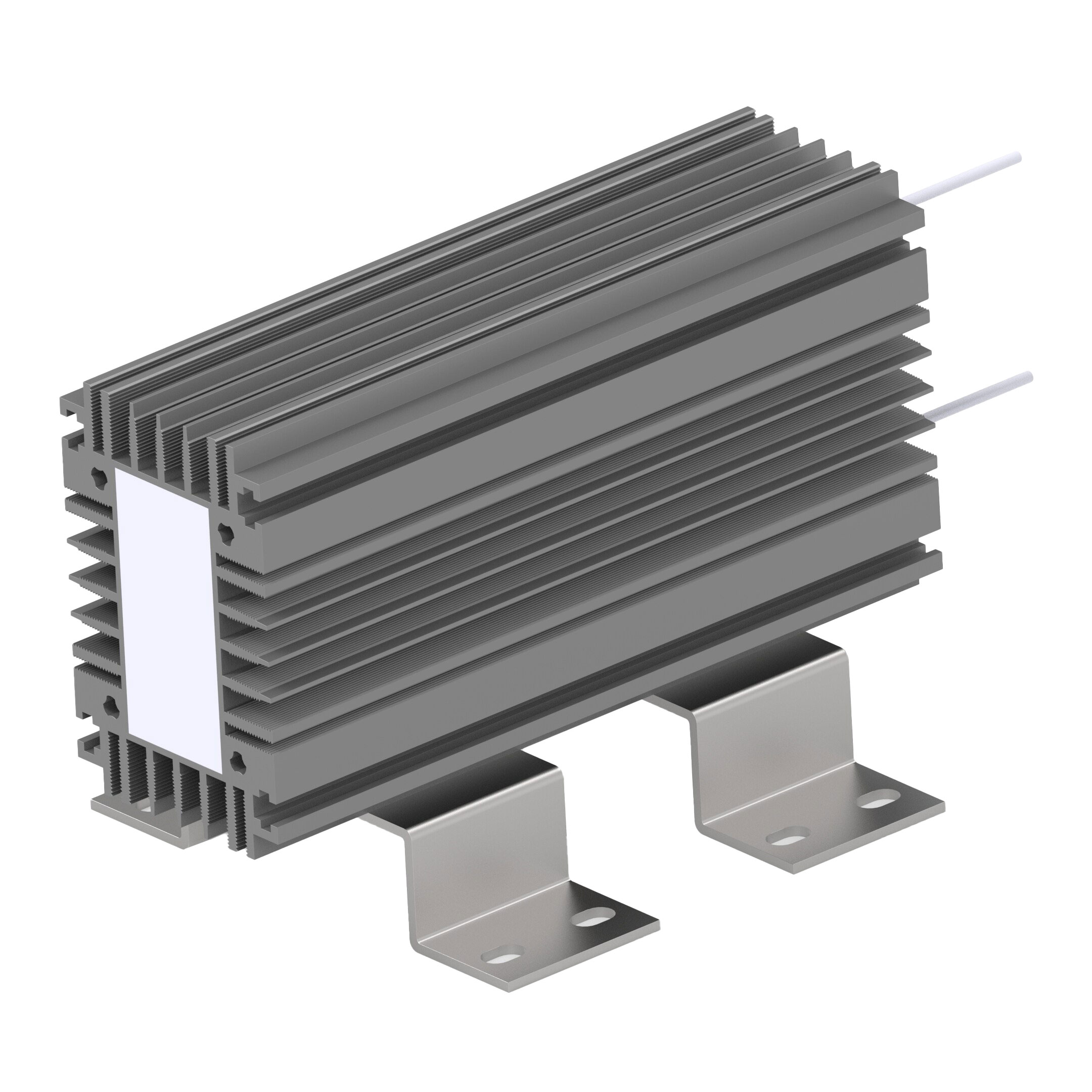

How do power resistors work?

2024-12-08

1

dict3_title

dict3_description